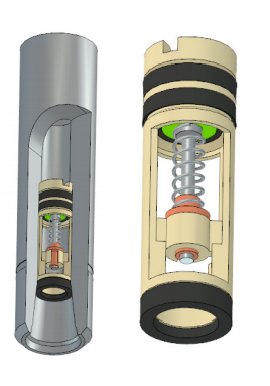

Hydraulic oscillators (Hydraulic Oscillator) play various important roles in oil drilling and other industrial applications. Here are their main functions:

1. **Reduce Frictional Resistance**:

- Hydraulic oscillators generate axial vibrations that transform the static friction between the drill string and the wellbore into dynamic friction, significantly reducing frictional resistance. This helps improve the effective transmission of drilling pressure and drilling efficiency, reducing wear and tear on the drill string and loss of drilling pressure due to friction.

2. **Increase Drilling Speed**:

- By reducing frictional resistance and optimizing the transmission of drilling pressure, hydraulic oscillators can increase drilling speed. They allow the drill bit to break rock more efficiently, shortening the drilling cycle and lowering drilling costs.

3. **Prevent Stuck Pipe**:

- The vibrations produced by the oscillator help prevent the drill string from getting stuck in the wellbore. The vibrations maintain a certain degree of movement between the drill string and the wellbore, reducing the risk of stuck pipe, especially when drilling through complex formations or long horizontal sections.

4. **Improve Drilling Pressure Transmission**:

- Hydraulic oscillators can enhance the transmission of drilling pressure from the surface to the bit. The vibrations reduce the loss of drilling pressure in the drill string, ensuring that more pressure reaches the bit and improves rock-breaking efficiency.

5. **Reduce Drill String Wear**:

- Lowering frictional resistance and preventing stuck pipe can reduce wear on the drill string. Hydraulic oscillators help extend the service life of the drill string, reducing the frequency of drill string replacements and saving costs.

6. **Enhance Drilling Safety**:

- By reducing the risk of stuck pipe and drill string wear, hydraulic oscillators improve the safety of drilling operations. They lower the risk of drilling accidents caused by drill string issues, ensuring the safety of personnel and equipment.

7. **Adapt to Complex Formations**:

- When drilling through complex formations, such as those prone to collapse, shrinkage, or high friction, hydraulic oscillators can better adapt to these conditions. The vibrations and reduced friction help the drill string pass through these formations more smoothly, reducing drilling difficulties.

8. **Assist Downhole Tool Operation**:

- The vibrations generated by hydraulic oscillators can assist in the operation of downhole tools, such as downhole motors, steering tools, and other equipment, improving their performance and reliability.

In summary, hydraulic oscillators play a crucial role in the drilling process. Through functions such as reducing friction, increasing drilling speed, and preventing stuck pipe, they provide strong support for the success and efficiency of drilling operations.