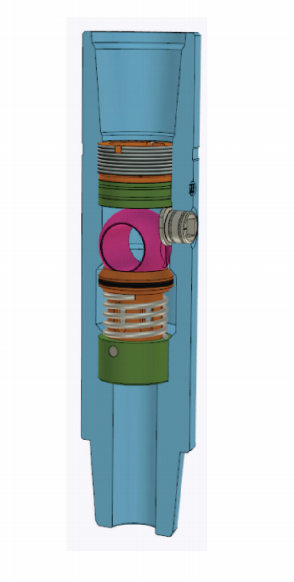

The Integral Screw Stabilizer is a crucial component in oil drilling operations, primarily used to maintain the stability and direction of the drill string. Here are its key functions:

1. Centralization of the Drill String

- The stabilizer helps keep the drill string centered within the borehole, reducing lateral vibrations and ensuring smoother drilling operations.

- This centralization minimizes contact between the drill string and the borehole walls, reducing wear and tear.

2. Directional Control

- In directional drilling, the stabilizer assists in controlling the trajectory of the drill bit, ensuring it follows the planned path.

- It helps maintain the desired angle and azimuth, which is critical for reaching the target reservoir.

3. Reduction of Vibration and Whirl

- The stabilizer dampens vibrations and prevents drill string whirl, which can cause damage to the drill bit, bottom hole assembly (BHA), and other equipment.

- This enhances drilling efficiency and extends the lifespan of drilling tools.

4. Improvement of Hole Quality

- By stabilizing the drill string, the tool helps maintain a consistent borehole diameter, reducing the risk of irregularities such as key seating or spiraling.

- This ensures a smoother and more stable wellbore, which is essential for subsequent operations like casing and cementing.

5. Enhanced Weight Transfer

- The stabilizer improves the transfer of weight from the drill string to the drill bit, ensuring effective penetration of the formation.

- This is particularly important in hard or abrasive formations where optimal bit performance is required.

6. Reduction of Differential Sticking

- By minimizing contact between the drill string and the borehole walls, the stabilizer reduces the risk of differential sticking, where the drill string becomes stuck due to pressure differences.

7. Support for Bottom Hole Assembly (BHA)

- The stabilizer provides structural support to the BHA, ensuring it remains aligned and functions effectively during drilling.

8. Adaptability to Downhole Conditions

- Integral screw stabilizers are designed to withstand harsh downhole conditions, including high pressures, temperatures, and abrasive environments.

In summary, the Integral Screw Stabilizer plays a vital role in ensuring efficient, safe, and accurate drilling operations by stabilizing the drill string, controlling direction, and improving overall drilling performance.