The Magnetic Interference Challenge

Conventional drill pipes distort critical surveying data:

-Azimuth errors >3° in high-latitude wells

-Total field distortion exceeding MWD tool compensation limits

-Well collision risks due to inaccurate trajectory data

Our solution delivers:

-<2 nT magnetic permeability (10x lower than standard pipes)

-ISO 10407-2 survey-grade accuracy

-Zero recalibration runs between sections

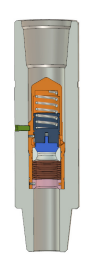

Manufacturing Excellence

✅ Cold Rolled Threads

40% longer fatigue life vs. cut threads

ATP thread inspection on every joint

✅ Double-Shoulder Design

200% higher torsional strength

Leak-proof seal to 15,000 psi

✅ Full-Body Hardbanding

Tungsten carbide matrix (HRC 65-68)

Casing wear reduction ≥70%

Field Performance Data

North Sea HPHT Wells: Zero magnetic interference at 185°C

Arctic Drilling: Azimuth accuracy ±0.1° at 85° inclination

Ultra-Deepwater: 12,000+ hours without degradation

Sour Gas Applications: NACE MR0175 compliant for H₂S service

Why Precision Matters

For MWD/LWD Systems:

Guarantees <0.5° azimuth error in 3D well paths

Enables 1.5m collision avoidance separation

Supports magnetic ranging for SAGD well pairs

For Drilling Engineers:

Eliminates dedicated non-magnetic drill collar (NMDC) strings

Reduces survey uncertainty factor by 4x

Enables GPS-level accuracy at 10,000ft TVD