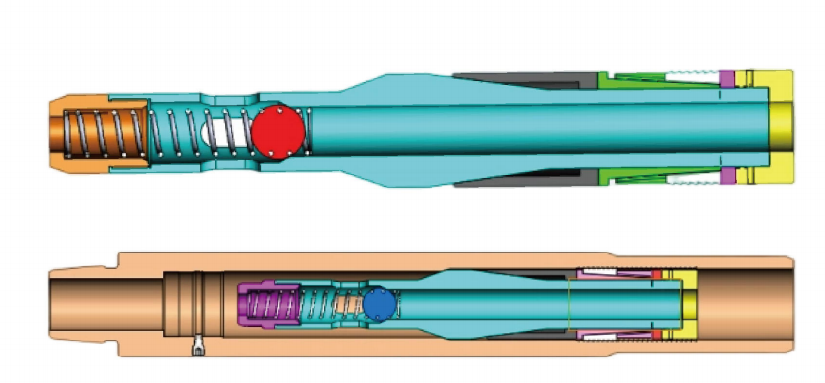

QDT Pulse Generator: Advanced Mud Pulse Telemetry for Reliable MWD Data Transmission

The Downhole Data Transmission Challenge

Conventional pulse generators face operational limitations:

⚠️ Signal attenuation in complex drilling fluid systems

⚠️ Component failure in high-vibration downhole environments

⚠️ Limited compatibility with different MWD system architectures

⚠️ Reduced reliability in extreme temperature and pressure conditions

Our QDT pulse generator delivers:

✅ Robust signal generation for reliable data transmission

✅ Enhanced durability in high-vibration drilling environments

✅ Broad system compatibility with major MWD platforms

✅ Proven performance in extreme downhole conditions

Technology & Working Principle

Advanced Pulse Generation Mechanism

| Component | Technology | Performance Benefit |

|---|---|---|

| Pulse Valve | High-speed servo-controlled mechanism | Precise pulse timing and shape control |

| Drive System | Electromechanical actuation | Fast response and high reliability |

| Control Electronics | Advanced DSP processing | Adaptive pulse optimization |

| Power Management | High-efficiency power system | Extended operation in power-limited environments |

Technical Specifications

| Parameter | Specification |

|---|---|

| Pulse Types | Positive, Negative, Continuous Wave |

| Data Rate | 0.5-3.0 bits/second (configurable) |

| Operating Pressure | Up to 25,000 psi |

| Temperature Rating | -25°C to 175°C |

| Power Requirements | 20-150 VDC, 0.1-2.0A |

| Compatibility | Major MWD system interfaces |

| Materials | Corrosion-resistant alloys |

| Pressure Drop | <50 psi at 500 GPM |

Operational Advantages

Signal Reliability

Strong signal amplitude maintains integrity in noisy environments

Adaptive pulse timing compensates for mud system variations

Error detection and correction capabilities

Durability & Maintenance

Extended service life through robust component design

Modular construction for easy field maintenance

Proven performance in abrasive drilling fluids

System Integration

Plug-and-play compatibility with major MWD systems

Flexible configuration for specific operational requirements

Comprehensive diagnostics for system health monitoring

Field Applications & Performance Data

Application Scenarios

Directional Drilling: Real-time toolface and inclination data transmission

Formation Evaluation: Logging while drilling data telemetry

HPHT Wells: Reliable performance in extreme conditions

Extended Reach Drilling: Consistent data transmission in long laterals

Performance Metrics

✅ Data Reliability: 99.5% successful data transmission rate

✅ Operational Uptime: 98% reliability in continuous operations

✅ Signal Strength: 15% improvement over previous generations

✅ Service Life: 2,000+ hours mean time between failures