The working principle of electronic single and multi-point inclinometers is primarily based on MEMS (Micro-Electro-Mechanical Systems) technology. Here is a detailed explanation of how they work:

Working Principle

- Measurement Principle:

Electronic single and multi-point inclinometers measure the tilt angle of an object relative to gravity using accelerometers. The accelerometer monitors the gravitational effect on a small mass block supported by an elastic structure. When the device tilts, this mass block slightly moves, causing a change in the capacitance between the mass block and the support structure. By measuring these capacitance changes, the tilt angle can be calculated.

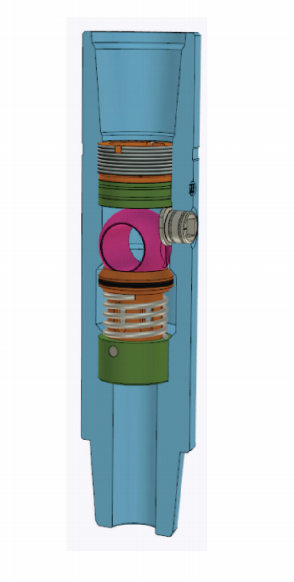

- Sensor Structure:

The sensor typically includes a fixed electrode and a movable proof mass electrode connected by a spring element. When the inclinometer is in a horizontal position, the capacitance between the two electrodes is measured. If the sensor tilts, the movable mass and its electrode change position relative to the fixed electrode, resulting in a change in capacitance between the two electrodes. The sensor unit measures this capacitance change and uses it to calculate the new tilt value.

- Data Processing:

The acceleration information collected by the sensor is internally converted and output as voltage values, divided into two channels: one for measuring acceleration in the X-axis direction and another for the Y-axis direction. These two voltage signals are processed through low-pass filters and operational amplifiers to amplify the output voltage, which is then sent to an A/D conversion module. The A/D conversion module outputs an 8-bit digital signal to a microcontroller for processing, which ultimately outputs serial data through a digital display circuit to show the platform's tilt angle.

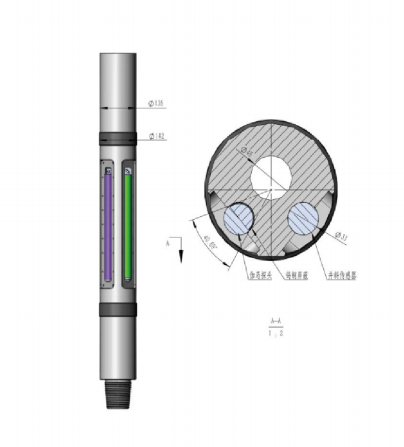

- Multi-Axis Measurement:

Electronic single and multi-point inclinometers typically contain two MEMS sensors installed perpendicularly to each other (dual-axis), allowing independent measurement of tilt angles in two vertical planes. This design enables the inclinometer to measure tilt angles in multiple directions, providing more comprehensive tilt information.

- Data Transmission:

Some electronic single and multi-point inclinometers connect to other devices or computers via an RS485 interface, allowing real-time transmission of measurement data. Data transmission typically uses asynchronous communication with 7 data bits, 2 stop bits, no parity, and a baud rate of 9600.

- Calibration and Precision:

To improve measurement accuracy, electronic single and multi-point inclinometers often use high-precision electrode arrays to enhance resolution and measurement accuracy. For static or near-static measurements, the movable mass in the sensor is physically damped to reduce sensitivity to frequencies above 29 Hz.