A drill pipe filter (or drill pipe debris filter) is a critical component in oil drilling operations, primarily designed to protect downhole equipment and ensure efficient fluid circulation. Its key functions include:

1. Solid Particle Removal

- Filters out abrasive debris (e.g., metal shavings, rock cuttings) from the drilling fluid before it enters the drill pipe or downhole tools.

- Prevents clogging of the drill bit nozzles, mud motor stators, or MWD/LWD tools, which could reduce drilling efficiency or cause tool failure.

2. Equipment Protection

- Extends the lifespan of sensitive components (e.g., mud pumps, valves, and measurement tools) by minimizing wear from abrasive particles.

- Reduces maintenance costs and downtime caused by particle-induced damage.

3. Fluid System Integrity

- Maintains clean drilling fluid to ensure optimal hydraulic performance, including lubrication, cooling, and cuttings transport.

- Prevents contamination that could alter mud properties (e.g., viscosity, density), ensuring stable wellbore pressure.

4. Pressure Management

- Avoids blockages in the drill string that could lead to sudden pressure spikes, reducing risks of stuck pipe or blowouts.

5. Compatibility with Advanced Tools

- Essential when using directional drilling tools (e.g., rotary steerable systems) or logging tools that require ultra-clean fluid for precise operation.

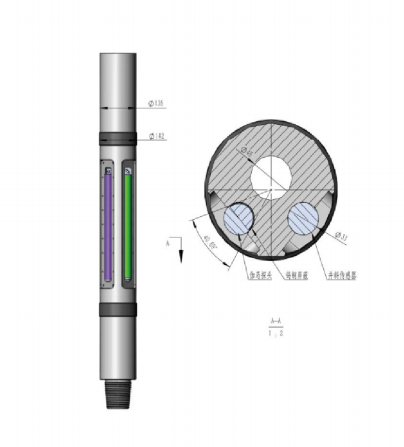

Typical Installation & Design

- Positioned at the top of the drill string (near the surface) or integrated into the drill pipe sub.

- Constructed with corrosion-resistant materials (e.g., stainless steel) and sieve-like mesh screens (mesh size tailored to formation conditions).

Common Scenarios for Use

- Drilling through unconsolidated formations prone to sanding.

- Re-entry wells with existing casing debris.

- Operations using oil-based or synthetic muds where particle control is critical.

By ensuring clean fluid circulation, the drill pipe filter enhances operational safety, reduces non-productive time (NPT), and optimizes overall drilling performance.