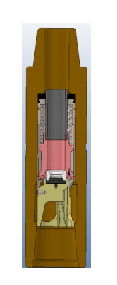

FDF Bypass Valve Working Principle: Emergency Circulation Mechanism

Fundamental Operating Concept

The FDF bypass valve operates on a pressure-differential activation principle, providing an alternative flow path when normal circulation through the bit becomes blocked.

Dual Operating Mode Mechanism

1. Normal Drilling Mode - Valve Closed

Component | Status | Function |

Main Flow Path | Open | 100% flow through bit nozzles |

Bypass Ports | Sealed closed | Metal-to-metal seal maintained |

Activation Piston | Hydraulically balanced | Held in upper position by spring force |

Pressure Differential | Below threshold (500-800psi) | Valve remains in default position |

Working Process:

Drilling fluid flows freely through the tool body

Minimal pressure loss (typically 50-100psi)

Spring mechanism maintains upward force on piston

All fluid exits through bit nozzles

2. Emergency Bypass Mode - Valve Open

Trigger Condition | Activation Mechanism | Resulting Action |

Bit nozzle plugging | Pressure differential increases | Piston moves downward |

800+ psi differential | Spring compression | Ports uncovered |

Flow obstruction | Hydraulic force overcomes spring | Alternative path established |

Activation Sequence:

Pressure Buildup: Bit nozzles plug, pressure increases upstream

Piston Movement: Differential pressure moves piston downward

Port Exposure: Bypass ports uncovered at specific stroke length

Flow Diversion: Fluid redirects through side ports

Circulation Resumed: Continuous flow maintained despite bit plugging

Key Components & Their Functions

-Differential Piston Assembly

Spring-Loaded Design: Pre-calibrated spring determines activation pressure

Balanced Seals: Dual seals prevent premature activation

Stroking Mechanism: Controlled movement ensures positive port opening

-Flow Diversion System

Side Ports: Strategically sized for adequate flow area (150-300% pipe ID)

Flow Channels: Optimized geometry for minimal turbulence

Erosion Protection: Tungsten carbide inserts in high-velocity areas

Technical Activation Parameters

Pressure Settings

Application | Activation Pressure | Reset Pressure |

Conventional Drilling | 500-800 psi | 200-400 psi |

High-Pressure Wells | 800-1200 psi | 400-600 psi |

Custom Settings | Adjustable 300-1500 psi | Proportional reduction |

Performance Characteristics

Response Time: 2-5 seconds from pressure spike to full flow

Flow Capacity: 80-100% of pump capacity through side ports

Pressure Loss: 100-200 psi through bypass system