Operation Workflow

Trip 1: Whipstock Setting

Run anchor assembly to target depth

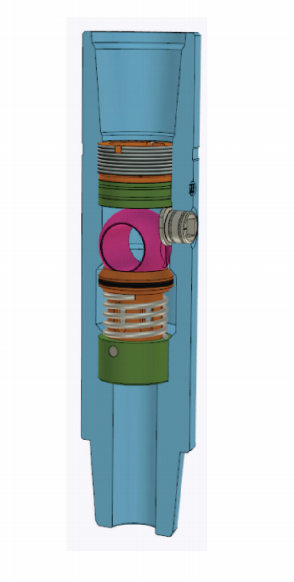

Apply 2,500psi to set permanent anchor

Confirm orientation with MWD

Trip 2: Window Milling

Start with pilot mill (Φ= casing ID + 10%)

Switch to window mill for full-section cut

Finish with reamer mill for edge smoothing

Special Features

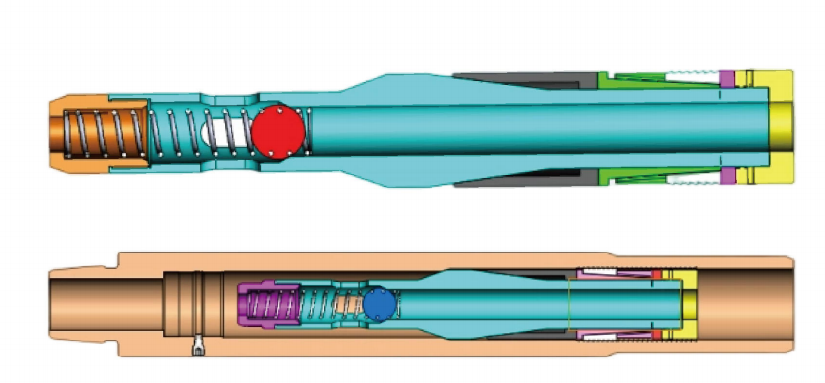

Composite Mill Design:

Stage 1: Diamond-enhanced pilot section

Stage 2: TCI (Tungsten Carbide Insert) main cutters

Stage 3: PDC finishing blades

Smart Anchor Technology:

Automatic pressure compensation

Anti-rotation lock for precise orientation

Debris Management:

Integrated junk slots (4x flow area)

Magnetized catcher for metal fragments

Target Applications

Well Type&Benefit

Workover Wells:Revive dead wells with new laterals

Multi-laterals:Create 2-3 branches from single parent

Bypass Drilling :Circumvent collapsed casing sections

Geothermal:Enable directional drilling in old holes