The Conventional Valve Limitation

Standard kelly cocks require:

-Separate check valve above kcock for full protection → added connections & failure points

-No circulation capability once closed → requires valve removal for killing operations

-Limited functionality in high-pressure differential environments

Our multi-function valve delivers:

✅ Integrated check/shutoff/circulation in single compact design

✅ 45MPa pressure differential operation

✅ -50°C to 190°C temperature range

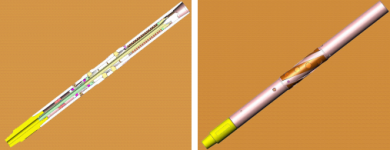

Triple-Function Technology

1. Advanced Materials Package

Body: API 4140/4145H steel with quench & temper treatment

Internals: 718 alloy & 17-4PH for H2S service (NACE MR0175)

Seals: Perfluoroelastomer compound (-50°C to 190°C)

2. High-Pressure Sealing Technology

Dual-seal system: Metal-to-metal primary, elastomer secondary

45MPa closing capability: Against full differential pressure

Zero-leak performance: API 6A PR2 testing protocol

Operational Advantages Over Conventional Valves

✅ Eliminates Additional Tools

No separate check valve required → reduces connection points by 50%

Single tool maintenance versus multiple valve inventory

✅ Enhanced Safety

Automatic check function prevents backflow during connections

Visual position indicator shows open/closed status

✅ Operational Flexibility

Circulate through valve during kill operations

Pressure equalization feature enables easy stabbing

Field Applications

HPHT Drilling: 190°C high-temperature operations

Sour Gas Fields: Full NACE MR0175 compliance for H2S service

Arctic Operations: -50°C low-temperature performance

Deepwater: 15,000psi working pressure rating

Underbalanced Drilling: Maintains pressure integrity during connections