The Top Drive Safety Challenge

In top drive drilling systems, emergency shutoff requires:

-Millisecond response to well kicks during continuous drilling

-Redundant barriers for both drilling and connection phases

-Compatibility with top drive quill and saver sub configurations

Our IBOP system delivers:

✅ 150ms hydraulic closure (upper IBOP)

✅ Manual backup (lower IBOP) for absolute reliability

✅ Direct top drive integration without adapters

Dual-Valve Protection Architecture

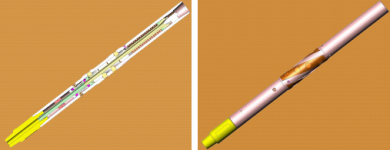

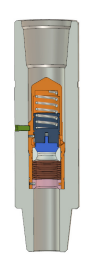

Upper IBOP - Hydraulic Instant Response

Component Specification

Actuator Type Hydraulic cylinder with failsafe spring

Closing Time <150 milliseconds

Control Method Solenoid valve (rig floor remote)

Connection Direct to top drive quill

Lower IBOP - Manual Redundant Backup

Component Specification

Operation 90° manual rotation

Location Below saver sub/protection joint

Function Secondary barrier during connections

Seal Type Metal-to-metal with elastomer backup

Technical Specifications

Parameter Specification

Pressure Rating 5,000psi, 10,000psi, 15,000psi options

Temperature Rating -50°C to 175°C (H2S service available)

Hydraulic Pressure 3,000psi operating pressure

Connections API 6A/7-1, including proprietary TDS

Materials 4140/4145H steel, alloy 625, 17-4PH

Compliance API Spec 8C, API RP 7G, NACE MR0175

Operational Advantages

✅ Instant Well Control

150ms closure during kicks while drilling

Dual barriers for redundant protection

✅ Top Drive Optimized

Direct mounting to quill shaft

No interference with pipe handling

✅ H2S Ready

NACE materials prevent sulfide cracking

Special seals for sour service

✅ Maintenance Friendly

Field-replaceable seals and actuators

Test ports for function verification

Field Applications

Offshore Drilling: 15,000psi rating for deepwater

Automated Rigs: Integration with Driller's Control System

Sour Gas Fields: NACE MR0175 compliance for H2S service

Arctic Operations: -50°C low-temperature operation

High-Speed Drilling: 150ms response for early kick detection