Hydraulic Expandable Stabilizer: Revolutionizing Drill String Performance

The Fixed Blade Stabilizer Limitation

Conventional stabilizers cause:

-Excessive drag & torque in directional wells costing $500K/well in fuel & equipment wear

-BHA whipping leading to MWD/LWD tool failures averaging $250K/incident

-Pack-off incidents during tripping resulting in 18-24 hours NPT

Our expandable stabilizer delivers:

✅ 40% reduction in drag & torque

✅ Eliminates bottom hole vibration

✅ Prevents fluid bypass packing

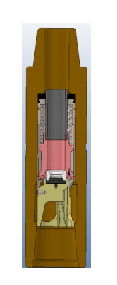

Flow Control Valve Manages expansion/retraction timing Prevents premature operation

→ Expands automatically when pumps are on

→ Retracts automatically when pumps are off

Operational Advantages Over Fixed Stabilizers

✅ Reduced Drag & Torque

40% lower rotational resistance than fixed-blade stabilizers

25% less weight on hook during tripping

✅ Enhanced Drilling Efficiency

30% faster tripping speeds without swab/surge effects

Eliminates "piston effect" during connections

✅ BHA Protection

Reduces lateral vibrations by 60%

Prevents MWD tool failures from shock loads

✅ Formation Compatibility

No pack-off in gumbo shale formations

Self-cleaning blade design prevents balling

Technical Specifications

Parameter/Specification

Gauge Range:8-1/2" to 12-1/4" (expandable 1-1/2")

Operating Pressure:300-3500 psi mud pressure

Response Time:15-30 seconds for full expansion

Connections:API REG, IF, FH (all standard sizes)

Materials:4145HM steel, tungsten carbide inserts

Temperature Rating:-20°C to 175°C

Field Applications

Directional Wells: Reduced torque in curve sections

Extended Reach Drilling: Enables longer laterals with less drag

Deepwater Operations: Prevents surging in narrow margin wells

Unconventional Shale: Eliminates pack-off in gumbo formations

Geothermal Drilling: High-temperature operation to 175°C