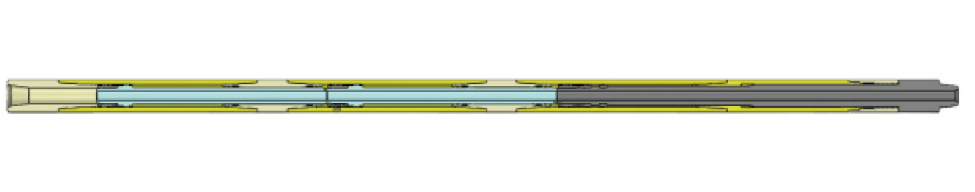

High-Strength Lifting Nipple: Drill Collar Performance in a Compact Package

The Heavy Lifting Challenge

In drilling and completion operations:

-Improper lifting points cause costly damage to premium threads

-Weight limitations of standard lift subs risk dropping expensive BHA components

-Connection mismatches lead to cross-threading and thread galling

Our lifting nipple delivers:

✅ Drill collar equivalent mechanical properties

✅ API spec connections for perfect thread engagement

✅ 250-ton working load capacity

Engineered for Heavy Loads

Material Science Excellence

Property | Standard Lift Sub | Our Lifting Nipple |

Yield Strength | 100-120 ksi | 135-155 ksi |

Impact Toughness | 40-50 J @ -20°C | 60-80 J @ -40°C |

Hardness | HRC 22-28 | HRC 28-32 |

→ AISI 4145HM modified alloy steel

→ Full quench and temper heat treatment

→ Ultrasonic testing on every unit

Technical Specifications

Parameter | Specification |

Size Range | 2-7/8" to 7-5/8" OD |

Thread Types | API REG, IF, FH, DS (double-shoulder) |

Working Load | 50 to 250 tons |

Shoulder Types | Straight shoulder / Tapered shoulder |

Material Grades | 4145HM, 4140, 4130 |

Compliance | API Spec 7-1, API RP 7G, ISO 10407-2 |

Design Configurations

Straight Shoulder Design

-Applications: Standard drilling operations

-Advantages: Maximum shoulder contact area

-Torque Capacity: 25,000 ft-lbs to 80,000 ft-lbs

Tapered Shoulder Design

-Applications: High-pressure sealing applications

-Advantages: Pressure seal to 15,000 psi

-Torque Capacity: 30,000 ft-lbs to 100,000 ft-lbs

Manufacturing Excellence

✅ Precision Threading

CNC machined to API spec tolerances

100% thread gauge inspection

✅ Heat Treatment

Controlled atmosphere quenching

Tempered to optimal hardness

✅ Surface Treatment

Phosphate coating for corrosion resistance

Optional hard banding for wear protection

Operational Benefits

✅ Safety Assurance

4:1 safety factor on all ratings

Non-destructive testing on every unit

✅ Connection Protection

Prevents damage to premium drill string connections

Perfect thread match to API specifications

✅ Versatility

Fits all makes of elevators and spiders

Multiple connection options available

Field Applications

BHA Handling: Safe lifting of bottom hole assemblies

Casing Running: Heavy weight casing string support

Completion Operations: Christmas tree and wellhead installation

Workover Operations: Tubing and drill pipe handling

Offshore Operations: DNV GL certified for marine applications