In the increasingly competitive oil drilling industry, improving drilling efficiency and reducing costs has become the core demand of enterprises. The Hydraulic Thruster, with its innovative working principle, outstanding performance advantages and high cost-effectiveness, provides a reliable solution for achieving high-speed, high-quality and low-cost drilling operations. It is not only a key tool for drilling speed increase.

Introduction to Hydraulic Thruster

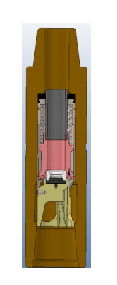

Hydraulic Thruster, also known as Hydraulic Pressurizer, is a high-performance energy conversion device widely used in oil drilling operations. It has revolutionized the traditional drilling pressure application method that relies on the weight of lower drill collars, bringing a new paradigm to oil drilling efficiency and quality.

Working Principle: Innovation Drives Performance

The core advantage of the Hydraulic Thruster lies in its advanced energy conversion mechanism. Instead of relying on the passive weight of drill collars, it utilizes a circulation pump to deliver drilling fluid, converting the fluid pressure energy into drilling pressure for the drill bit through the pressure difference on the upper and lower sides of the piston and the pressure build-up at the drill bit. This innovative design also enables flexible connection between the drill bit (or lower connected drilling tools) and the rest of the drill string, effectively overcoming the drawbacks of rigid pressure application.

Core Advantages: Creating Multiple Value Points

By optimizing the drilling state of the drill bit, the Hydraulic Thruster achieves a series of key benefits that significantly enhance drilling operations: First, it provides excellent shock absorption and anti-bit bouncing functions, effectively reducing the damage to the drill bit and drilling tools caused by vibration and irregular movement. Second, it realizes automatic bit feeding, ensuring stable and continuous drilling pressure application, which avoids the problems of uneven drilling pressure caused by manual operation. Third, it significantly improves drilling speed and efficiency—by maintaining an optimal drilling state, it shortens the drilling cycle and reduces operating costs.

Product Highlights: Cost-Effective and Easy to Operate

As a cost-effective drilling speed-increasing tool, the Hydraulic Thruster combines three core advantages: low cost, easy operation, and high efficiency. It does not require complex supporting equipment or specialized technical personnel for operation and maintenance, which reduces the threshold for application. At the same time, its stable performance and long service life further lower the overall operating cost for drilling enterprises, making it an ideal choice for improving drilling economic benefits.