High-Temperature MWD Intelligent Calibration Bench: Precision Measurement for Downhole Tools

The High-Temperature Calibration Challenge

Traditional calibration methods face critical limitations:

⚠️ Insufficient temperature range not matching downhole conditions

⚠️ Magnetic interference affecting measurement accuracy

⚠️ Manual operations requiring skilled technicians and extended time

⚠️ Limited parameter coverage missing critical temperature drift data

Our high-temperature MWD calibration bench delivers:

✅ 300°C operational range simulating real downhole conditions

✅ 0.0013° measurement accuracy for all critical parameters

✅ Non-magnetic construction eliminating external interference

✅ Automated intelligent control with comprehensive data analysis

Advanced Calibration Technology

Oil-Bath Heating System

| Component | Specification | Advantage |

|---|---|---|

| Heating Medium | High-temperature thermal oil | Uniform heat distribution, no hotspots |

| Temperature Range | 25°C to 300°C | Covers all downhole conditions |

| Control Accuracy | ±1°C | Precise temperature management |

| Heating Method | Intelligent oil furnace | Stable, consistent performance |

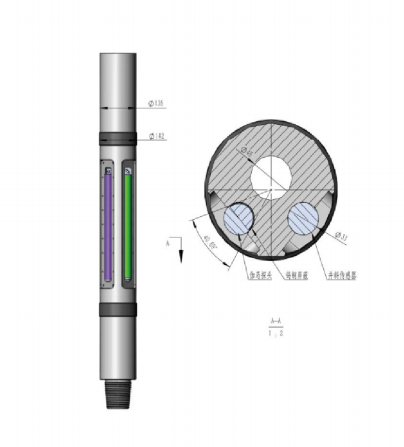

High-Precision Measurement System

| Sensor Type | Quantity | Precision | Measurement Parameter |

|---|---|---|---|

| 18-bit High Accuracy | 3 units | 0.0013° | Azimuth, Inclination, Toolface |

| Temperature Sensors | Multiple | ±0.1°C | Temperature profiling |

| Data Acquisition | High-speed | 0.001° resolution | Real-time parameter tracking |

Technical Specifications

| Parameter | Specification |

|---|---|

| Dimensions | 1000 × 1000 × 1530 mm |

| Weight | 260 kg |

| Temperature Range | 25°C to 300°C |

| Temperature Control | ±1°C accuracy |

| Measurement Accuracy | 0.0013° (all angles) |

| Power Supply | AC 220V |

| Computer Interface | USB |

| Data Output | Serial RS232 |

| Construction Material | Non-magnetic alloys |

Operational Advantages vs Traditional Benches

Precision & Accuracy

0.0013° measurement precision for azimuth, inclination, and toolface

18-bit high-resolution sensors capturing minute variations

Real-time temperature compensation ensuring measurement integrity

Advanced Features

Toolface measurement capability for directional drilling tools

Temperature drift analysis characterizing probe performance across temperatures

Automated calibration procedures reducing operator dependency

User Experience

Intelligent control system with intuitive computer interface

Comprehensive data display with real-time parameter monitoring

Compact non-magnetic design (260kg total weight) for lab flexibility

Application Scope & Compatibility

Supported Tool Types

MWD (Measurement While Drilling) systems

Wireline probe systems

Electronic multi-shot survey tools

Electronic single-shot instruments

Various diameter and specification inclinometers

Industry Applications

Oilfield services companies for tool maintenance and calibration

Directional drilling contractors for precision tool verification

Research institutions developing advanced survey tools

Quality assurance departments for manufacturing validation