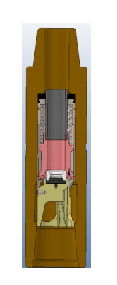

Drilling Safety Bypass Tool: Integrated Solution for Lost Circulation & Stuck Pipe

The Lost Circulation & Stuck Pipe Challenge

Conventional methods face critical limitations:

-PBL tools restrict flow path and block fishing/logging tools

-Multiple trips required for different operations

-Limited functionality in severe loss zones

-Inability to perform back-off when stuck

Our safety bypass tool delivers:

✅ Infinite bypass cycles with simple ball drop activation

✅ Full bore access when closed - no flow restrictions

✅ Integrated functions - circulation and back-off capability

✅ No tripping required between operations

Working Principle: Ball-Activated Control

Dual-Mode Operation Mechanism

Operation Mode | Activation Method | Flow Path | Function |

Normal Drilling | Pumps operating, no ball | Through main bore | Standard drilling |

Bypass Mode | Ball seated + pump pressure | Through side ports | Lost circulation control |

Back-off Mode | Special tool + pressure | Tool-specific path | Emergency disconnect |

Technical Specifications

Parameter | Specification |

Size Range | 4-3/4" to 9-1/2" OD |

Connection Types | API REG, IF, FH (all standards) |

Pressure Rating | 5,000psi / 10,000psi options |

Ball Seat Size | 1-1/2" to 3" diameter options |

Port Area | 200-400% of drill pipe ID area |

Materials | 4145HM, tungsten carbide seats |

Activation Pressure | 1,000-1,500psi above circulating |

Field Application Procedures

Lost Circulation Treatment

-Detect losses during drilling operations

-Drop activation ball through drill string

-Increase pump pressure to open bypass ports

-Pump LCM through side ports directly to loss zone

-Stop pumps to close ports when treatment complete

Fishing & Logging Operations

-Tools pass freely through full bore when closed

-No restrictions for overshot tools or logging instruments

-Immediate conversion back to drilling mode after operations

Stuck Pipe Back-off

-Activate emergency release mechanism

-Apply torque while maintaining pressure

-Disconnect at designated point in string

Retrieve upper section while leaving tool in hole

Operational Advantages

✅ Eliminate Tripping

Treat losses immediately without pulling out of hole

Save 18-24 hours per incident

✅ Full Functionality

Unrestricted bore for fishing and logging

Multiple treatment cycles without tool replacement

✅ Enhanced Safety

Quick response to well control situations

Built-in emergency disconnect capability