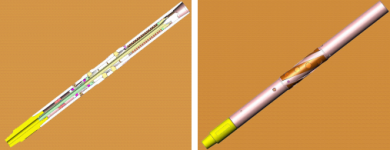

Auto-Fill Float Valve: Revolutionary Self-Filling Technology for Safer Tripping Operations

The Manual Filling Challenge in Conventional Operations

Traditional float valves create operational inefficiencies and risks:

-Manual filling required every 800-1000 meters during tripping

-Incomplete filling leads to air columns and well control risks

-Extended tripping time reduces overall drilling efficiency

-Potential for human error in filling operations

Our patented auto-fill float valve (ZL202410917438.X) delivers:

✅ Automatic filling during entire tripping process

✅ One-click switch to kick prevention mode when pumping

✅ Guide pin positioning ensures reliable operation

✅ Eliminates manual intervention completely

Working Principle: Intelligent Dual-Mode Operation

Automatic Filling Mode (Tripping In)

Component | Function | Innovation |

Flow Channel | Automatically opens during tripping | Patented pressure differential design |

Valve Mechanism | Allows mud inflow from annulus | Self-actuating without manual control |

Filling Control | Maintains continuous filling | Prevents air column formation |

Kick Prevention Mode (Pumping Operations)

Operation | Activation | Safety Feature |

Pump Startup | Automatic mode switch | Instant response to pressure |

Guide Pin Lock | Positive positioning | Prevents accidental opening |

Full Sealing | Metal-to-metal seal | 10,000psi pressure rating |

Technical Specifications

Parameter | Specification |

Patent Number | ZL202410917438.X |

Pressure Rating | 5,000psi / 10,000psi options |

Activation Method | Automatic pressure response |

Fill Rate | Match tripping speed automatically |

Materials | 4145HM steel, corrosion-resistant alloys |

Connections | API REG, IF, FH (all standard sizes) |

Temperature Rating | -20°C to 175°C |

Operational Advantages

-Safety Improvement

Eliminates air columns - maintains continuous hydrostatic pressure

Prevents well control incidents caused by incomplete filling

Reduces human error in filling operations

-Efficiency Gains

Saves 30-45 minutes per 1,000 meters of tripping

Continuous tripping without stopping for manual filling

Simplified operations - no additional equipment required

-Cost Reduction

Reduces tripping time by 15-20%

Minimizes non-productive time associated with manual filling

Decreases labor requirements for filling operations