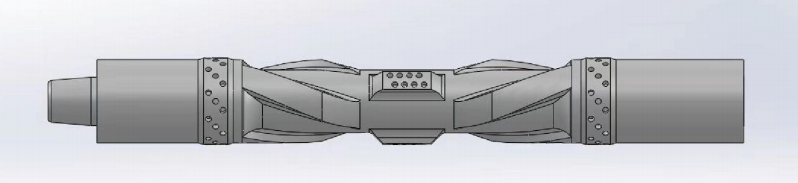

Flapper-Type Float Valve: Essential Backflow Prevention for Drilling Operations

The Backflow Contamination Challenge

During pipe connections, uncontrolled backflow causes:

-Bit nozzle plugging with cuttings → 4-8 hours NPT per incident

-Drill string corrosion from abrasive sediment ingress

-Well control risks from underground blowouts during connections

Our flapper-type float valve delivers:

✅ Instant 2-second closure upon pump stoppage

✅ 10,000psi wellbore pressure sealing capability

✅ API 7-1 certification for reliable performance

How It Works: Automatic Flow Control

Dual-Function Protection System

Operation Mode | Mechanical Action | Result |

Normal Drilling | Flapper held open by flow pressure | Continuous circulation |

Pump Stoppage | Flapper instantly closes via spring & differential pressure | Prevents backflow |

Kick/Blowout | Well pressure forces flapper into sealed position | Contains pressure in string |

→ Spring-assisted closure for instant shutoff

→ Pressure-balanced design prevents premature closing

Technical Specifications

Parameter | Specification |

Pressure Rating | 5,000psi & 10,000psi options |

Closure Time | <2 seconds from flow reversal |

Temperature Rating | -50°C to 175°C |

Material Grades | 4140 steel, 410/420 stainless, alloy 625 |

Connections | API REG, IF, FH (all standard sizes) |

Compliance | API Spec 7-1, API RP 59, NACE MR0175 |

Operational Benefits

✅ Eliminate Nozzle Plugging

Zero backflow during connections → save 16 rig hours/well

Reduced bit trips from plugged nozzles

✅ Enhanced Well Control

Secondary barrier during kicks

Contains pressure inside drill string

✅ Extended Tool Life

Hard-coated flapper resists erosion

Replaceable seal rings for multiple runs

Field Applications

Deepwater Drilling: 10,000psi rating for HPHT wells

Slimhole Operations: Compact design for 3-1/2" strings

Underbalanced Drilling: Prevents gas influx up string

Geothermal Wells: High-temp elastomers for 175°C service