Auto-Protected Drill Float Valve: Advanced Erosion Resistance with Reliable Well Control

The Erosion Failure Challenge in Conventional Float Valves

Traditional float valves suffer from critical limitations:

⚠️ Rapid erosion failure in abrasive drilling fluids - 50-100 hour lifespan

⚠️ Unreliable sealing after minimal wear creates well control risks

⚠️ Frequent replacements costing $20K+ per valve in downtime and parts

⚠️ Backflow contamination causing bit nozzle plugging and drill string damage

Our patented auto-protected float valve (ZL202010103281.9) delivers:

✅ 3x longer service life through erosion-resistant design

✅ Automatic closure during well control events

✅ Reliable backflow prevention during connections

✅ Consistent performance throughout drilling operations

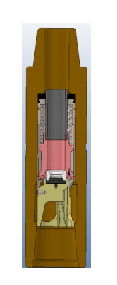

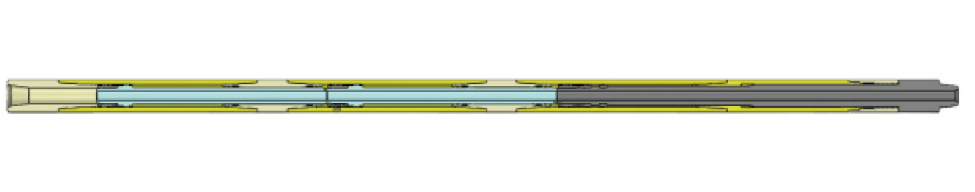

Working Principle & Protection Mechanism

Dual-Mode Automatic Operation

| Operation Mode | Valve Status | Flow Condition | Protection Function |

|---|---|---|---|

| Normal Drilling | Open | Downward circulation | Unrestricted flow path |

| Kick/Blowout | Automatic closure | Upward flow attempt | Positive well control barrier |

| Connections | Spring-assisted closure | Static/backflow | Prevents cuttings ingress |

Patented Erosion Protection System

Enhanced Material Technology:

Special alloy construction resistant to abrasive wear

Hardened sealing surfaces maintaining integrity after repeated cycles

Corrosion-resistant components for harsh drilling environments

Advanced Flow Dynamics:

Optimized flow path reduces turbulent erosion

Protected sealing surfaces away from direct fluid impingement

Reinforced critical areas where conventional valves fail first

Technical Specifications

| Parameter | Specification |

|---|---|

| Patent Number | ZL202010103281.9 |

| Pressure Rating | 5,000psi / 10,000psi / 15,000psi options |

| Temperature Rating | -20°C to 175°C |

| Cycle Life | 1,000+ operations without performance degradation |

| Materials | Special erosion-resistant alloy steel |

| Connections | API REG, IF, FH (all standard sizes) |

| Closure Time | <2 seconds from flow reversal detection |

Operational Advantages

Safety Enhancement

Automatic kick response without operator intervention

Reliable well control during unexpected pressure events

Continuous protection throughout drilling operation

Cost Reduction

Extended service life reduces replacement frequency by 3x

Minimized downtime from valve-related issues

Reduced inventory needs due to longer operational life

Performance Reliability

Consistent operation in abrasive drilling fluids

Maintained sealing capability throughout service life

Compatibility with all standard drilling practices

Field Applications & Performance Data

Application Scenarios

High-Rate Drilling with abrasive mud systems

Exploratory Wells with unknown pressure regimes

Deepwater Operations requiring reliable well control

Extended Reach Drilling with extended service requirements