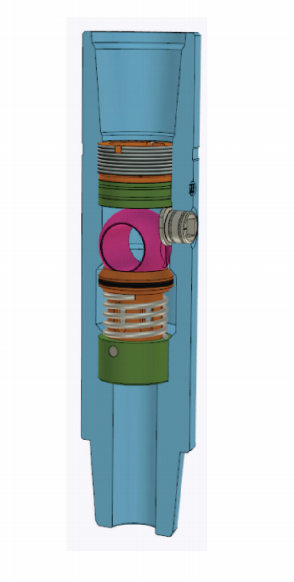

MWD Stabilizer: Essential Centering and Protection for Downhole Measurement Tools

The MWD Tool Vibration and Positioning Challenge

Poor MWD tool positioning causes:

⚠️ Inaccurate survey data from sensor misalignment

⚠️ Premature tool failure from excessive vibration

⚠️ Poor signal quality affecting data transmission

⚠️ Reduced tool life from uncontrolled lateral movement

Our MWD stabilizer delivers:

✅ Optimal tool centralization for accurate sensor readings

✅ Vibration damping to extend MWD/LWD tool life

✅ Non-magnetic properties ensuring clean survey data

✅ Enhanced drilling performance through stabilized BHA

Design Features & Working Principle

Stabilization Technology

| Feature | Specification | Functional Benefit |

|---|---|---|

| Non-Magnetic Material | Austenitic stainless steel | Eliminates magnetic interference with MWD sensors |

| Optimized Blade Design | Helical or straight blades with controlled clearance | Maximum centralization with minimum pressure drop |

| Wear Protection | Tungsten carbide hardfacing | Extended service life in abrasive formations |

| Precision Machining | Tight diameter tolerance | Consistent standoff from wellbore wall |

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | 316L Stainless Steel (Non-Magnetic) |

| Magnetic Permeability | <1.005 μ |

| Blade Configuration | Helical 3-blade or Straight 4-blade |

| Standoff | 75-85% of hole diameter (customizable) |

| Pressure Rating | 10,000psi / 15,000psi / 20,000psi options |

| Temperature Rating | -20°C to 175°C |

| Connections | API REG, IF, FH (all standard sizes) |

Operational Advantages

Data Accuracy Improvement

Consistent sensor positioning for reliable survey measurements

Reduced magnetic interference with non-magnetic construction

Stable tool environment minimizing measurement errors

Equipment Protection

Vibration damping extends MWD/LWD tool service life

Shock absorption protects sensitive electronic components

Reduced maintenance costs through decreased tool failure rates

Drilling Performance

Improved weight transfer to bit through stabilized BHA

Better hole cleaning with optimized annular flow

Reduced stick-slip in directional applications

Field Applications & Performance Data

Application Scenarios

Directional Drilling: Stabilized MWD positioning for accurate geosteering

High-Angle Wells: Vibration control in extended reach applications

Complex Formations: Protection against shock loads in erratic drilling

Deepwater Operations: Reliable performance in narrow margin wells

Performance Metrics

✅ Data Accuracy: 30% improvement in survey reliability

✅ Tool Life: 40% extension in MWD/LWD service intervals

✅ Vibration Reduction: 60% decrease in harmful lateral vibrations

✅ Drilling Efficiency: 15% improvement in ROP through better weight transfer