The working principle of the remotely operated variable diameter stabilizer involves several key technologies and design features. Here is the basic working principle:

1. **Multi-stage Variable Diameter Capability**:

- The remotely operated variable diameter stabilizer can adjust its diameter in multiple stages by changing the status of the pins in the travel control wheel guide slots under the action of drilling fluid driving force. This design allows the stabilizer to adapt its diameter according to changes in downhole conditions, fitting various borehole sizes and geological conditions.

2. **Hydraulic Power Control**:

- By installing a fluid circulation device, the flow rate of circulating water can be controlled, thereby obtaining different pressure losses, simulating downhole pressure changes. This hydraulic power control is key to achieving the variable diameter function of the stabilizer.

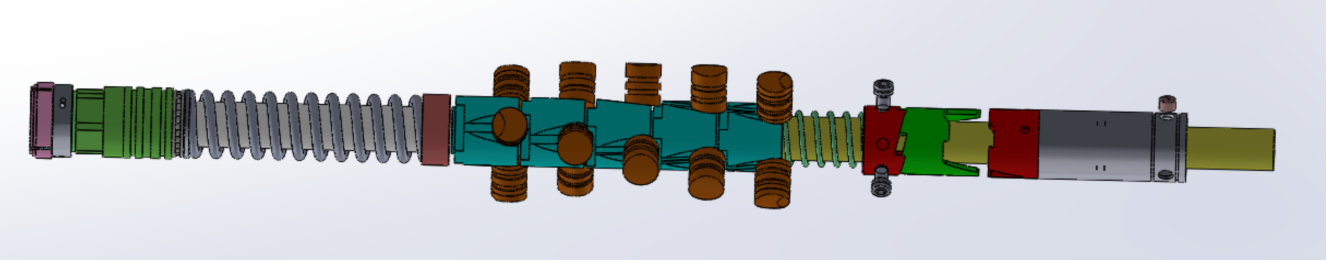

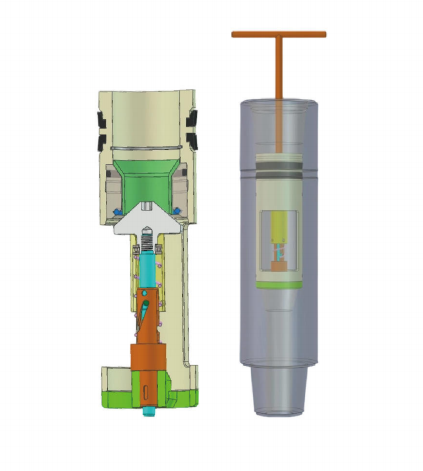

3. **Structure and Working Mechanism**:

- The structure of the remotely operated variable diameter stabilizer includes key components such as the travel control wheel, guide slots, and pins. These components work together to enable the stabilizer to automatically adjust its diameter in response to changes in drilling fluid pressure, adapting to the downhole environment.

4. **Remote Control Operation**:

- The variable diameter operation of the stabilizer can be achieved through remote control, meaning that operators can adjust the stabilizer's diameter in real-time based on changes in downhole conditions, optimizing drilling performance.

5. **Theoretical Calculation and Finite Element Analysis**:

- To delve into the study of the remotely operated variable diameter stabilizer, theoretical calculations and finite element analyses are combined to reveal the tool's structure and working principles. This helps understand the stabilizer's role in controlling borehole trajectories and optimize its design.

6. **Mechanical Model Establishment**:

- Establish a mechanical model of the drill string assembly (BHA) using the remotely operated variable diameter stabilizer and set up a torque balance equation based on static equilibrium conditions to study the impact of the stabilizer on borehole trajectory control.

7. **Optimized Design**:

- Multiple parameters of the stabilizer are optimized through multi-objective optimization methods to reduce weight and improve economic performance. For example, by changing the double-clamped blade root design to a circular blade root and optimizing dimensions, the maximum stress value and weight of the blade root can be significantly reduced.

In summary, the remotely operated variable diameter stabilizer, through its unique design and control mechanisms, can dynamically adjust its diameter during the drilling process to adapt to different downhole conditions, thereby improving drilling efficiency and the accuracy of borehole trajectory control.