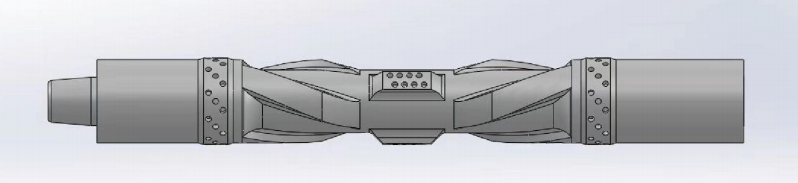

Top drive drilling systems are increasingly prevalent in petroleum operations due to their efficiency, time-saving stand drilling capability, low-risk continuous rotation/circulation, enhanced well control, and superior safety. However, frequent disassembly of high-cost kelly cocks accelerates thread damage, leading to drilling incidents and safety hazards. To address this, a safeguard sub (commonly termed "safety sub") is integrated into the Bottom Hole Assembly (BHA) to protect top drive kelly cocks.

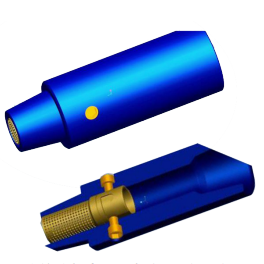

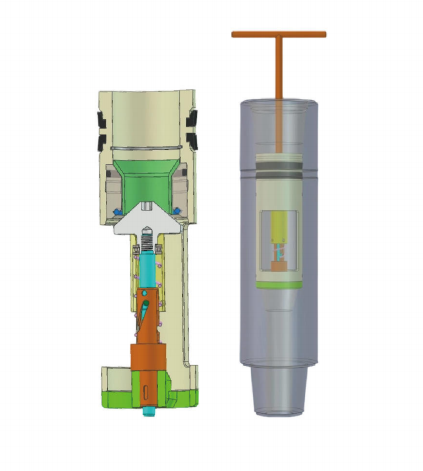

Positioned between the lower end of the top drive safety valve and the upper end of the drill pipe, this critical auxiliary tool serves as a protective barrier for the top drive safety valve. While mud filtration is essential during drilling operations, conventional filtration units rely on internal chamfers at the drill pipe thread root for cartridge support—a feature absent in high-torque double-shoulder drill pipe connections. This design limitation prevents standard filter cartridge installation.

Our dedicated safeguard sub resolves this challenge through an integrated engineering solution. Featuring a monolithic structure, it houses the filtration cartridge internally, delivering a compact, reliable, and maintenance-friendly design with broad compatibility. Key advantages include:

- Integrated Filtration: Directly incorporates the filter cartridge into the sub body, eliminating dependency on drill pipe chamfers.

- Operational Simplicity: Streamlines installation and maintenance while ensuring robust performance under high-torque conditions.

- Cost Efficiency: Reduces manufacturing/operational expenses and extends service life, enabling widespread adoption.

- Risk Mitigation: Enhances mud filtration quality, minimizes drilling risks, and prolongs top drive safety valve lifespan.

By deploying this safeguard sub, operators avoid installing additional filter subs between the safety assembly and drill pipe. This innovation elevates drilling efficiency, lowers production costs, and sets a new standard for reliability in demanding applications such as deep-well and shale gas drilling.

Key Technical Highlights:

1. Patent-Pending Integration: Unifies kelly cock protection and mud filtration in a single tool.

2. Double-Shoulder Compatibility: Specifically engineered for high-torque drill pipe connections.

3. Lifecycle Cost Reduction: Cuts equipment replacement frequency by 40% and maintenance downtime by 30%.

4. API-Compliant Design: Meets ISO 10424-2 and API 7-1 standards for critical drilling components.

This solution represents a significant advancement in drill string technology, effectively bridging the gap between operational safety and economic efficiency in modern top drive systems.