In today’s era of advancing oil and gas exploration and development into deeper and more complex formations, drilling engineering faces increasingly severe challenges. Particularly, with the growing number of extended-reach wells and horizontal wells, coupled with the continuous extension of horizontal displacement, issues such as increased friction, ineffective weight on bit (WOB) transmission, and unstable tool face have become more prominent, severely restricting drilling efficiency and safety. Against this backdrop, the hydraulic oscillator, as a key downhole tool, has emerged as an important technical support to solve drilling challenges in complex well conditions, thanks to its unique working principle and remarkable application effects.

Structural Composition: A Precisely Coordinated Core Architecture

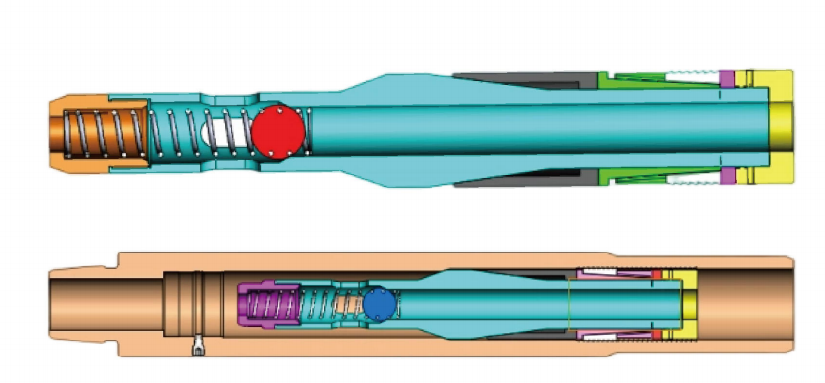

The efficient operation of a hydraulic oscillator relies on its scientifically rigorous mechanical structure, which mainly consists of three core components working in synergy: the oscillating sub, the power section, and the valve and bearing system. The oscillating sub is the key executive component responsible for generating vibrational output, converting power into longitudinal vibrational energy through its specific structural design. The power section provides a continuous and stable power source for the entire tool, ensuring the effective output of vibrational energy. The valve and bearing system, on the other hand, undertakes crucial functions such as flow control, pressure regulation, and reducing internal friction, guaranteeing the tool’s long-term stable operation in high-pressure, high-load downhole environments. These three parts work closely together to form a complete vibration generation and transmission mechanism, laying a solid foundation for optimizing drilling performance.

Working Principle: An Innovative Logic of Breaking Through with Vibration

The core working principle of the hydraulic oscillator lies in using self-generated longitudinal vibration to overcome the bottleneck of WOB transmission in traditional drilling. In conventional drilling processes, as the wellbore trajectory extends (especially in horizontal sections and extended-reach segments), friction between the bottom hole assembly (BHA) and the wellbore wall increases significantly. This makes it difficult for the WOB applied at the surface to be effectively transmitted to the drill bit, not only affecting the rate of penetration (ROP) but also posing risks of stuck pipe and torsional vibration.

The hydraulic oscillator addresses this by driving the oscillating sub to generate periodic longitudinal vibration through its power section. This vibrational energy effectively offsets the frictional resistance between the drill string and the wellbore wall, allowing WOB to be transmitted more smoothly along the drill string to the bit. Meanwhile, the vibration reduces rigid contact between the drill string assembly and the wellbore, lowering the probability of sticking and alleviating fatigue damage to the drill string caused by torsional vibration, thereby fundamentally improving the effectiveness and stability of WOB transmission.

Core Advantages: Comprehensive Optimization of Drilling Performance

The application of hydraulic oscillators brings multi-dimensional improvements to drilling engineering, with its core advantages manifested in the following aspects:

- Precise WOB Transmission: Whether in conventional vertical wells or complex directional wells, hydraulic oscillators ensure stable WOB transmission. Even in complex formations with frequent changes in azimuth, the drill bit can receive continuous and uniform pressure, avoiding ROP reduction due to insufficient WOB.

- Reduced Failure Risks: By minimizing friction and rigid contact between the drill string and the wellbore wall, the occurrence of common failures such as stuck pipe and torsional vibration is significantly reduced. This extends the service life of the drill string and lowers the incidence of downhole accidents.

- Stable Tool Face Control: In directional drilling, the stability of the tool face directly affects the accuracy of the wellbore trajectory. The hydraulic oscillator, through stable vibrational output, reduces frequent fluctuations of the tool face, minimizing the workload of manual tool face adjustments and making the drilling process more efficient and precise.

- Enhanced Rate of Penetration (ROP): Stable WOB transmission, reliable tool face control, and effective suppression of frictional resistance ultimately translate into a significant increase in ROP, shortening the drilling cycle and reducing engineering costs.

Application Scenarios: Technical Breakthroughs Focused on Complex Well Conditions

The value of hydraulic oscillators is particularly prominent in complex well conditions. As oil and gas exploration expands into deep formations and marginal oilfields, the demand for drilling extended-reach wells, ultra-long horizontal wells, and wells in complex lithological formations is increasing. These scenarios commonly face challenges such as high friction, difficult WOB transmission, and complex tool face control.

In directional drilling, especially when using downhole motors for trajectory adjustment, hydraulic oscillators effectively improve WOB transmission efficiency, ensuring the wellbore extends according to the designed trajectory. In extended-reach and horizontal wells, their friction-reducing effect significantly enhances the ability to extend horizontal sections, helping to reach farther target zones. In complex formations with drastic azimuth changes, their stable tool face control ensures drilling accuracy and reduces the number of trajectory corrections. It can be said that hydraulic oscillators provide a simple, efficient, and reliable solution to drilling challenges in complex well conditions.

Conclusion: Efficient Innovation Empowering Drilling Engineering

With its unique longitudinal vibration principle, precise structural design, and remarkable application advantages, the hydraulic oscillator has become an indispensable key tool in modern drilling engineering. It not only solves the "bottleneck" problems of traditional drilling in complex well conditions but also injects new impetus into the efficient development of oil and gas resources by optimizing WOB transmission, reducing failure risks, and improving drilling efficiency. In the future, as drilling technology continues to evolve, hydraulic oscillators will continue to exert their technical advantages, facilitating the successful development of more complex well types and providing solid support for the high-quality development of the oil and gas industry.