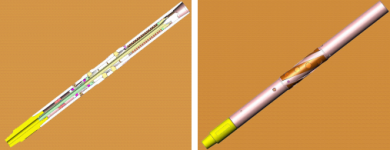

LWD Resistivity Measurement Tool: Integrated Multi-Parameter Formation Evaluation

The Challenge of Traditional Logging While Drilling

Conventional LWD systems face integration limitations:

-Multiple tools required for complete formation evaluation

-Extended tool strings increasing BHA length and complexity

-Separate data streams requiring complex integration

-Limited real-time capabilities for immediate decision making

Our integrated LWD resistivity tool delivers:

✅ Multiple measurements in single compact tool

✅ Real-time formation evaluation while drilling

✅ Shortened tool string with integrated sensors

✅ Simultaneous data acquisition for comprehensive analysis

Integrated Sensor Technology Architecture

Multi-Sensor Configuration

Sensor Module | Components | Measurement Capability |

Gamma Measurement | Two gamma sensors | Azimuthal gamma ray, formation density |

Tool Orientation | Three accelerometers, two fluxgates | Inclination, azimuth, tool face |

Resistivity Array | Four transmitters, two receivers | Multi-depth resistivity, formation boundaries |

Data Acquisition | High-speed processors | Real-time data processing and transmission |

Technical Specifications

Parameter | Specification |

Tool OD | 6.75" standard (custom sizes available) |

Gamma Sensors | Dual scintillation detectors |

Orientation Sensors | Tri-axial accelerometers, dual fluxgate magnetometers |

Antenna Configuration | 4 transmitter, 2 receiver array |

Data Transmission | Mud pulse or wired drill pipe |

Temperature Rating | 175°C |

Pressure Rating | 25,000 psi |

Measurement Depth | 1-10 meter depth of investigation |

Working Principle & Measurement Advantages

Simultaneous Multi-Parameter Acquisition

Gamma Measurement Module:

-Dual sensor configuration provides statistical accuracy

-Azimuthal measurement identifies formation boundaries directionally

-Real-time correlation with resistivity data for comprehensive analysis

Tool Orientation Module:

-Tri-axial accelerometers measure gravity vector for inclination

-Dual fluxgate magnetometers determine magnetic field for azimuth

-Continuous tool face monitoring for directional control

Resistivity Array Module:

-Multiple transmitter-receiver spacings provide different depths of investigation

-Multi-frequency operation enables complex formation analysis

-Real-time resistivity imaging for geosteering decisions

Operational Benefits

✅ Compact Design

30% shorter tool length compared to separate tools

Reduced BHA complexity with integrated sensors

✅ Enhanced Data Quality

Synchronized measurements from all sensors

Real-time quality control with cross-verification between sensors

✅ Improved Drilling Efficiency

Immediate formation evaluation without stopping drilling

Faster decision making with integrated data presentation

Field Applications & Case Study

Application Scenarios

Geosteering Operations: Real-time boundary detection and well placement

Formation Evaluation: Comprehensive petrophysical analysis while drilling

Well Placement Optimization: Maximizing reservoir contact in complex formations

Hazard Avoidance: Early detection of problematic zones