Non-Magnetic Drill Collar: Guaranteeing Precision in Wellbore Surveying

The Critical Challenge of Magnetic Interference

In directional drilling, standard steel components distort essential survey data, leading to:

-Inaccurate Azimuth Readings: Deviations exceeding 3° in high-latitude wells.

-Increased Collision Risks: Unreliable data raises the potential for wellbore collisions.

-Costly Corrective Actions: Requires additional runs and trajectory corrections, resulting in non-productive time.

Our Non-Magnetic Drill Collar delivers:

✅ Ultra-Low Magnetic Permeability (<1.005 μ) for survey-grade accuracy.

✅ Unmatched Trajectory Control, enabling precise well placement.

✅ Full Compliance with API and SY/T5144 standards.

Engineered for Uncompromising Accuracy

Advanced Material Science

Property | Conventional NM Collar | Our Innovation |

Magnetic Permeability | 1.05 - 1.10 μ | ≤ 1.005 μ |

Core Material | Standard Austenitic Stainless Steel | Proprietary Low-Carbon Stainless Steel |

Corrosion Resistance | Moderate (PREN 28-32) | High (PREN 38-42) |

→ Proprietary Low-Carbon Stainless Steel eliminates magnetic hotspots.

→ Controlled Forging & Heat Treatment ensures uniform non-magnetic properties throughout the collar.

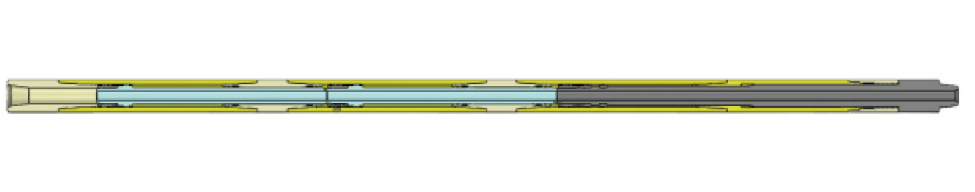

Technical Specifications

Parameter | Specification |

Size Range | 3-1/2" to 9-1/2" OD |

Standard Length | 9.1m / 30ft (Custom lengths available) |

Thread Connections | API NC31 to NC77, 4-1/2" FH to 7-5/8" FH |

Special Threads | Double-Shoulder, VAM, TMK, and other premium connections |

Pressure Rating | 15,000 psi Internal / 10,000 psi External |

Compliance | API Spec 7-1, SY/T5144, ISO 10407-2 |

Manufacturing Excellence & Durability

✅ Cold Rolled Thread

40% Longer Fatigue Life compared to cut threads.

Automated Thread Inspection on every collar ensures perfect geometry.

✅ Double-Shoulder Connection Option

200% Higher Torsional Strength than API connections.

Superior Gas-Tight Seal for high-pressure applications.

✅ Robust Construction

Full-Body Hardbanding (Optional) reduces casing wear by up to 70%.

H₂S Service options available with NACE MR0175 compliant materials.

Field-Proven Performance & Applications

Deepwater & HPHT Wells: Maintains integrity and accuracy at 175°C+.

Sour Gas Fields: NACE MR0175 compliant materials resist sulfide stress cracking.

Arctic Drilling: Reliable performance in extreme low-temperature environments.

Complex Wellpaths: Essential for ERD, horizontal, and multi-lateral wells requiring precise geomagnetic referencing.