High-Energy Rubber Rotating Casing Saver Sub: Dual-Action Protection for Drilling Operations

Solve Critical Drilling Challenges

Metal-to-Casing Abrasion causes:

-$250K-$1M/well casing replacement costs

-34% drill string failure risk in ERD wells

-HSE incidents from worn casing leaks

Excessive Torque leads to:

⛔ ROP reduction >30% in lateral sections

⛔ Stuck pipe events costing $120K/day

How Our Technology Works

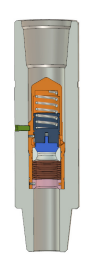

Dual-Function Mechanical Design

Component | Role | Innovation |

Viscoelastic Rubber Sleeve | Absorbs lateral loads | Self-lubricating polymer (0.08 CoF) |

Precision Mandrel | Transfers rotation | Hardened 4140 steel + WC coating |

Bearing Interface | Enables 360° rotation | 250 RPM continuous operation |

→ Converts destructive friction into rotational energy

→ Creates buffer zone between tool joints & casing

Quantifiable Operational Benefits

✅ Casing Integrity Protection

Reduce wear rates by ≥80% (API TR 7PER15K verified)

Extend casing life through 3+ wells

✅ Drilling Efficiency Boost

Lower surface torque 18-25%

Enable higher RPM in curves (dogleg severity ≤8°/100ft)

✅ Cost & Risk Reduction

Save $150K-$400K/well on premature casing replacement

Decrease stuck pipe risk by 40%

Technical Specifications

◆ Connections: API NC46-NC77, 6-5/8" REG-7-5/8" REG

◆ Temp Rating: -40°C to 175°C (H₂S/CO₂ resistant)

◆ Max OD/ID: 12.25"/3.25"

◆ Load Capacity:

Axial Static: 800,000 lbf

Dynamic Side Load: 45,000 lbf

◆ Certifications: ISO 10407-2, API Q1

Ideal Applications

Shale Gas Horizontals: Protect production casing in 10,000ft laterals

Deepwater Wells: Mitigate wear in riser-critical zones

Salt Dome Drilling: Prevent casing wear in corrosive formations

Geothermal Projects: High-temp operation to 175°C