Top Drive Saver Sub for Double-Shoulder Drill Pipe: All-in-One Protection & Filtration Solution

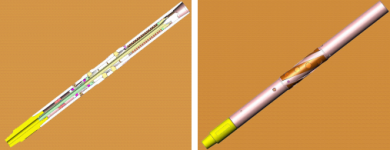

The Double-Shoulder Drill Pipe Challenge

In modern top drive drilling systems:

-IBOP valve threads wear rapidly from frequent handling - $15K replacement cost per valve

-No filter placement in double-shoulder connections due to missing chamfer

-Extra filter subs add connections & failure points in string

-Poor mud filtration leads to tool damage and drilling dysfunction

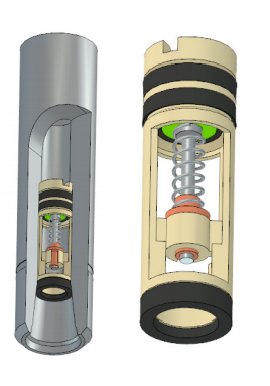

Our specialized saver sub delivers:

✅ Integrated filtration without additional sub

✅ 300% longer IBOP thread life

✅ API standard connections for universal compatibility

Quantifiable Operational Benefits

✅ Cost Reduction

Eliminates $8K filter sub per string

Saves $15K per IBOP through thread protection

Reduces handling time by 50% during connections

✅ Improved Reliability

Fewer connections in string → lower failure risk

Consistent filtration throughout run

Maintains torque integrity of double-shoulder design

✅ Enhanced Safety

Prevents debris-related tool failures

Reduces handling of heavy IBOP valves

Technical Specifications

Parameter | Specification |

Upper Connection | API 6-5/8" REG, 7-5/8" REG (IBOP thread) |

Lower Connection | Double-shoulder 4-1/2", 5-1/2", 6-5/8" |

Filter Rating | 0.5mm (500 micron) stainless mesh |

Pressure Rating | 10,000psi working pressure |

Material | 4145HM quenched & tempered |

Temperature Rating | -20°C to 175°C |

Compliance | API Spec 7-1, API RP 7G |

Field Applications

High-Torque Applications: Maintains double-shoulder torque capacity

HPHT Wells: 175°C temperature rating

Sour Gas Operations: NACE MR0175 materials available

Extended Reach Drilling: Reduces string connections

Automated Rigs: Compatible with iron roughnecks