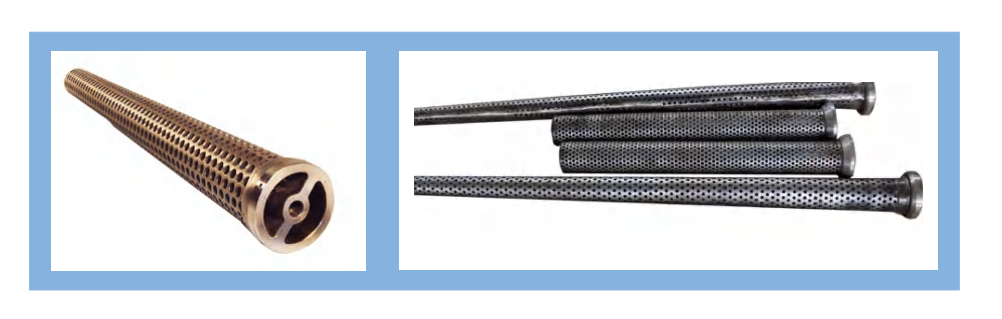

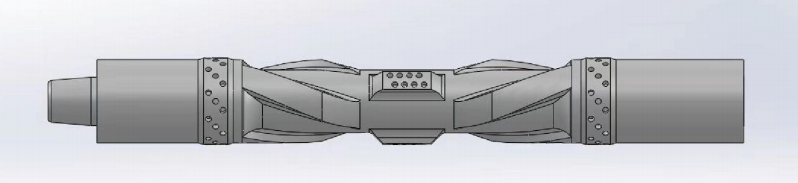

A drill pipe filter (also known as a drill pipe screen or drill pipe debris filter) is a critical component in oil drilling operations. It is designed to prevent debris, cuttings, and other unwanted materials from entering the drill string or circulating system, ensuring smooth and efficient drilling operations. Below are the primary functions of a drill pipe filter in oil drilling:

---

1. Debris and Contaminant Removal

- Prevents Blockages: The filter captures large debris, metal shavings, and other contaminants that could otherwise enter the drill string and cause blockages.

- Protects Downhole Equipment: By filtering out solid particles, it protects sensitive downhole tools and equipment, such as mud motors, MWD (Measurement While Drilling) tools, and LWD (Logging While Drilling) tools, from damage.

---

2. Improves Drilling Fluid Quality

- Maintains Mud Properties: The filter helps maintain the quality and properties of the drilling fluid (mud) by removing solid particles that could alter its viscosity, density, or other characteristics.

- Enhances Fluid Circulation: Clean drilling fluid circulates more efficiently, reducing the risk of pump wear and improving overall drilling performance.

---

3. Reduces Equipment Wear and Tear

- Protects Pumps and Valves: By removing abrasive particles, the filter reduces wear and tear on mud pumps, valves, and other surface equipment.

- Extends Equipment Lifespan: Cleaner drilling fluid reduces the frequency of equipment maintenance and extends the lifespan of drilling components.

---

4. Enhances Drilling Efficiency

- Prevents Downtime: By preventing blockages and equipment failures, the filter minimizes downtime and keeps drilling operations running smoothly.

- Improves Rate of Penetration (ROP): Clean drilling fluid and unobstructed equipment contribute to better drilling performance and faster penetration rates.

---

5. Safety and Environmental Protection

- Reduces Risk of Accidents: By preventing equipment failures and maintaining fluid circulation, the filter helps reduce the risk of accidents, such as blowouts or stuck pipe incidents.

- Environmental Compliance: Proper filtration ensures that drilling fluids are handled and disposed of in an environmentally responsible manner, reducing the risk of contamination.

---

6. Cost Savings

- Reduces Maintenance Costs: By protecting equipment and reducing wear, the filter lowers maintenance and repair costs.

- Minimizes Fluid Loss: Efficient filtration reduces the need for frequent fluid replacements, saving on drilling fluid costs.

Conclusion

The drill pipe filter is an essential tool in oil drilling operations, ensuring the smooth circulation of drilling fluids, protecting equipment, and enhancing overall drilling efficiency. By preventing debris from entering the drill string, it contributes to safer, more cost-effective, and environmentally responsible drilling operations.