A casing cutter is a specialized tool used in oil drilling operations to remove or cut sections of casing that have been installed in a wellbore. The primary functions of a casing cutter in oil drilling include:

1. Casing Removal

- Decommissioning Wells: When a well is no longer productive or needs to be abandoned, the casing cutter is used to remove sections of the casing to facilitate proper well abandonment procedures.

- Workover Operations: During workover operations, it may be necessary to remove damaged or corroded sections of casing to allow for repairs or replacements.

2. Section Milling

- Window Cutting: Casing cutters can be used to create a window in the casing to allow for sidetracking, which is the process of drilling a new wellbore from an existing one.

- Slot Cutting: In some cases, slots are cut into the casing to allow for the installation of new equipment or to facilitate the flow of fluids.

3. Wellbore Access

- Accessing Reservoirs: Casing cutters can be used to remove sections of casing to access different reservoirs or zones within a wellbore.

- Fishing Operations: In situations where tools or equipment are stuck in the wellbore, a casing cutter can be used to remove obstructing sections of casing to retrieve the stuck items.

4. Environmental Protection

- Plugging and Abandonment: Properly cutting and removing casing is crucial for environmental protection, ensuring that wells are securely plugged and abandoned to prevent any potential contamination.

5. Cost Efficiency

- Reducing Costs: By efficiently removing sections of casing, operators can reduce the costs associated with well abandonment, workovers, and sidetracking operations.

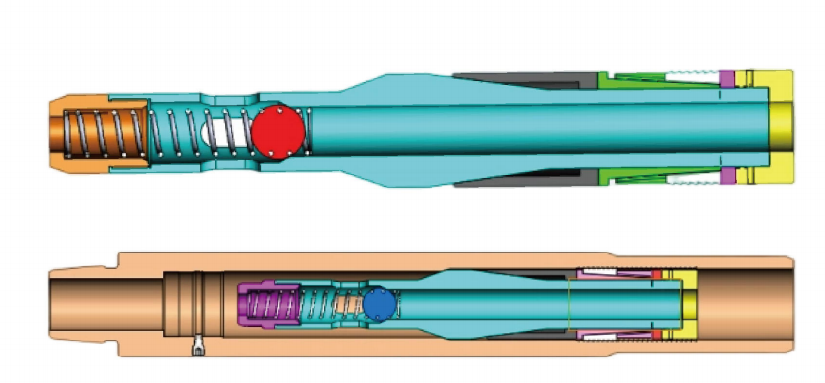

Types of Casing Cutters

1. Mechanical Casing Cutters: Utilize mechanical force to cut through the casing. These are often used in shallower wells.

2. Hydraulic Casing Cutters: Use hydraulic pressure to drive the cutting mechanism, suitable for deeper and more challenging well conditions.

3. Explosive Casing Cutters: Employ controlled explosions to sever the casing, typically used in more complex or difficult cutting scenarios.

Operational Considerations

- Depth and Pressure: The choice of casing cutter depends on the depth and pressure conditions of the well.

- Casing Material and Thickness: Different cutters are designed to handle various materials and thicknesses of casing.

- Wellbore Conditions: The presence of fluids, debris, and other wellbore conditions can influence the selection and operation of a casing cutter.

Conclusion

Casing cutters play a crucial role in various stages of oil drilling and well maintenance. They ensure that operations such as well abandonment, workovers, and sidetracking are conducted efficiently and safely, ultimately contributing to the overall success and environmental responsibility of oil drilling activities.