Core functions and working principles

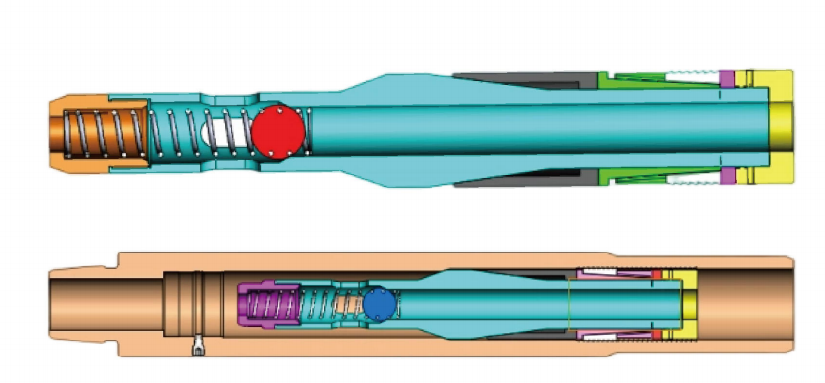

1. Hydraulic pressurization:

Core mechanism: Utilize the hydraulic energy of the circulating drilling fluid (mud) during the drilling process to apply the required drilling pressure to the drill bit.

Problem solving: Directly addressing the difficulty of "pressurization", especially in working conditions such as sliding drilling (directional), large displacement wells, horizontal wells, and small boreholes, overcoming the problem of high friction between the drill string and the wellbore wall, and difficulty in effectively transmitting drilling pressure to the drill bit.

Unique advantage: It can compensate for the loss of drilling pressure caused by sliding drilling, ensuring that the drill bit can also obtain stable and effective drilling pressure in directional or complex sections.

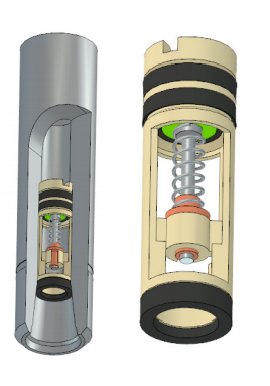

2. Hydraulic shock absorber:

Function: Absorb and buffer the impact and vibration encountered by the drill bit during the drilling process (such as formation changes, jumping, stick slip vibration, etc.).

Effect: Protect drill bits and drilling tools (such as drill collars, screw motors, MWD/LWD instruments, etc.), extend their service life, and improve the stability and safety of drilling operations.

3. Automatic drilling:

Function: The tool can automatically and continuously apply drilling pressure to the drill bit according to the settings or working conditions.

Effect: Reduce the labor intensity of manual control of drilling pressure by the driller, achieve a smoother and more stable drilling process, and help improve mechanical drilling speed and wellbore quality.

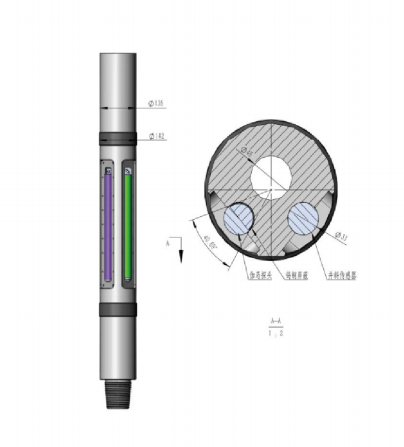

4. Anti inclination and straightening:

Principle: By providing stable and controllable hydraulic pressurization, the problem of wellbore deviation caused by drill string bending, insufficient pendulum effect, or uneven pressurization can be reduced or avoided.

Objective: To achieve "anti inclination quick drilling" in vertical wells or sections that require control of wellbore inclination (including directional wells), that is, to efficiently drill vertical or low dogleg wellbore that meets design requirements.

Core advantages and effects

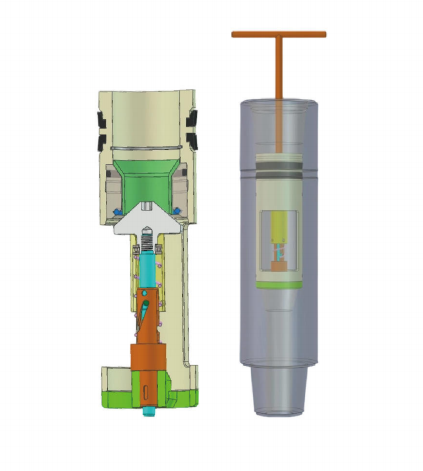

1. Improve drilling speed (ROP): Stable bit pressure and shock absorption help the drill bit break rocks more efficiently.

2. Reduce the labor intensity of the driller: The automatic drill feeding function reduces the frequent adjustment of the brake by the driller.

3. Protecting drill bits and drilling tools: The shock absorption function effectively reduces impact loads and extends the service life of expensive downhole tools.

4. Solve the problem of pressurization: Especially suitable for scenarios where conventional methods of pressurization are difficult, such as large displacement wells, horizontal wells, directional wells (especially sliding drilling sections), and small boreholes.

5. Implement anti inclination and fast drilling: In straight wells or sections that require control of inclination, increase drilling speed while ensuring wellbore quality.

6. Compensate for drilling pressure loss: effectively compensate for the drilling pressure consumed due to friction during sliding drilling.

Main application scenarios

1. Difficult working conditions for pressurization: large displacement wells, horizontal wells, directional wells (especially during the sliding drilling stage)

slim-hole drilling

2. Vertical well anti inclination quick drilling: For ordinary vertical wells, it is necessary to increase the drilling speed and strictly control the wellbore section with inclination. Efficient and high-quality drilling in inclined formations.

3. Pressure damping for ordinary vertical wells: Even in conventional vertical wells, it is used to provide smoother drilling pressure, absorb vibration, and achieve the purpose of protecting drilling tools and optimizing drilling.

summarize

Hydraulic pressure shock absorber is an intelligent downhole tool that uses drilling fluid to achieve pressure, shock absorption, and automatic drilling. It solves the key problem of difficult transmission of drilling pressure in complex structured wells (horizontal wells, large displacement wells, directional wells) and small boreholes, while significantly improving drilling speed, protecting drilling tools, reducing manual operation intensity, and effectively assisting in achieving the goal of "anti deviation and fast drilling" in vertical drilling. It is an important technical equipment for improving drilling efficiency, safety, and economy.