In petroleum drilling operations, well blowout emergency response is a critical safety concern. Conventional kelly cock valves (typically kept in the open position) offer sufficient flow area for quick connection to implement inside BOP closure. However, their functionality is limited to shutoff only, lacking check valve capability. Crucially, when operational conditions require the valve to be positioned below the rotary table, it must remain in the constant open state. This leaves the drill string without internal well control equipment at this critical section. To compensate, field operations often require installing an additional check valve above the kelly cock, increasing operational complexity and potential risks.

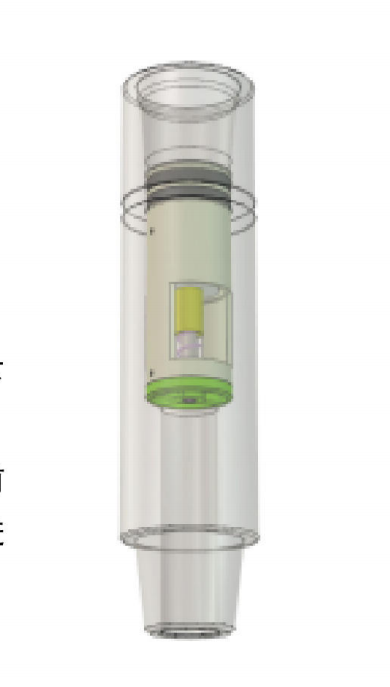

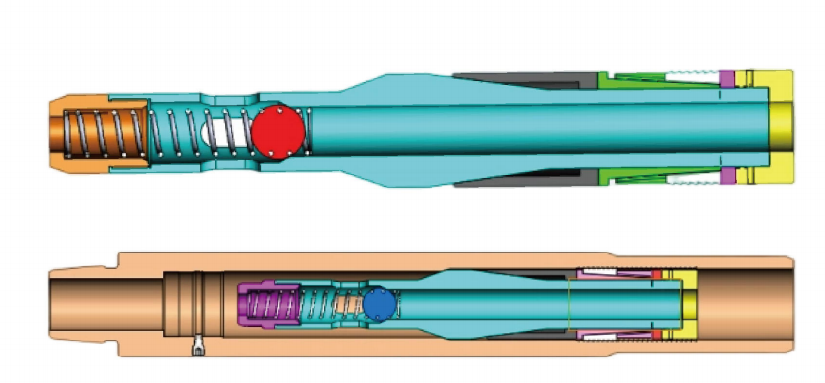

Addressing this technical limitation, this invention introduces a Multifunctional Kelly Cock Valve. Featuring a simple, compact, and novel design, it delivers exceptional reliability, truly achieving "multi-purpose in one valve" with strong compatibility. It is an advanced well control device specifically developed for the petroleum industry drilling sector.

Core Advantages and Performance Characteristics

1. Integrated Multifunctionality: Pressure Release, Blowout Prevention & Kill Circulation

Utilizing a unique floating ball valve mechanism, the valve enables three key functions:

Easy Pressure Release for Tool Alignment: Open the ball valve effortlessly to release internal string pressure for tool alignment.

Reliable Blowout Prevention: Close the ball valve to instantly block wellbore fluid influx, effectively preventing blowouts.

Efficient Kill Circulation: Utilize the floating ball feature to establish circulation channels for well kill operations.

2. High Strength & Superior Sulfide Stress Cracking (SSC) Resistance

The valve body is manufactured strictly from high-strength steel compliant with API standards, ensuring robust and durable construction.

Internal critical components are precision-engineered from special alloys resistant to sulfide stress cracking.

Combined with high-precision machining, this guarantees the superior quality and long service life essential for petroleum drilling well control safety tools.

3. High Opening Pressure Differential & Reliable Sealing

The control mechanism incorporates advanced sealing technology, significantly enhancing sealing reliability under high pressure.

With internal drill string pressure differentials up to 45MPa, the valve ensures smooth and reliable opening or closing operations, meeting stringent well control requirements.

4. Wide Temperature Tolerance

Specially formulated sealing materials enable an extreme operational temperature range (-50°C to +190°C).

This allows reliable performance in diverse harsh environments, from arctic conditions to high-temperature deep wells.

Summary: This multifunctional kelly cock valve successfully integrates core functions—pressure release, blowout prevention, and kill circulation—through its innovative floating ball design. It overcomes the limitation of conventional valves lacking check functionality in specific scenarios, eliminating the need for an additional check valve. Its outstanding performance in high strength, SSC resistance, high-pressure sealing, and broad temperature range significantly enhances drilling safety and operational efficiency, representing a crucial upgrade in drilling well control equipment.