The Critical Spillage Challenge

During kelly/pipe connection in oil & gas drilling/workover operations, residual drilling mud inside the kelly bar and upper drill string often sprays uncontrollably onto the drill floor. This causes:

1. HSE Hazards: Slippery surfaces increasing fall risks

2. Environmental Violations: Soil/water contamination from toxic mud

3. Operational Losses: $50-200/barrel mud waste + cleanup downtime

4. Equipment Corrosion: Accelerated degradation of rig components

How Mud Saver Valves Solve This

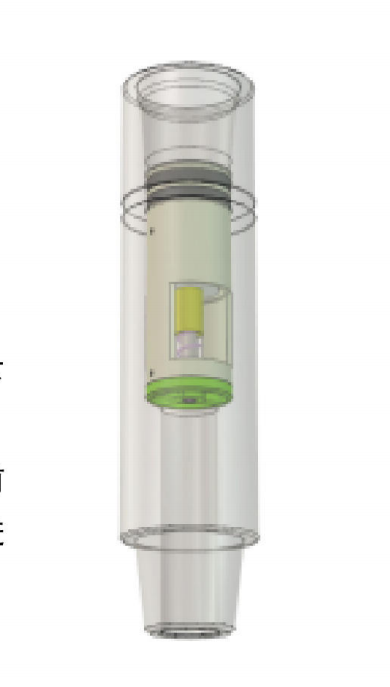

Installed below the kelly or lower kelly cock, these specialized valves automatically seal the drill string during connections:

1.Close instantly when the kelly is disconnected

2.Trap 100% residual mud inside the string

3.Reopen automatically when new pipe is connected

→ Eliminates spillage at the source

Key Technical Features

Property&Specification

Installation:Below kelly/lower kelly cock

Pressure Rating:5,000-10,000 psi (API 6A/16A standards)

Seal Type :Spring-actuated ball/poppet valve

Material:316SS/Hastelloy with erosion-resistant trim

Temp Range: -20°C to 120°C

Operational & Economic Benefits

1.Reduce Mud Costs: Save 3-8% of total fluid volume per well

2.Cut Cleanup Time: Eliminate 30-60 min/day of NPT (non-productive time)

3.HSE Compliance: Meet OSHA/EPA spill prevention regulations

4.Extend Equipment Life: Prevent corrosion on drawworks/BOPs

Industry Applications

1.Land & Offshore Drilling Rigs

2.Workover/Well Servicing Units

3.Geothermal Drilling Operations

4.Top Drive Systems