I. Structural Composition

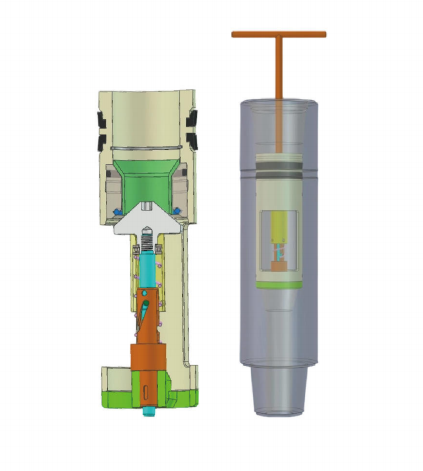

1. Main Components:

- Knob and Actuation Mechanism: Controls valve opening/closing via a specialized wrench.

- Ball Valve Assembly: Includes a floating ball and movable valve seat.

- Fixed Valve Seat: Forms the primary sealing surface with the movable seat.

- Enlarged Chamber: A specialized cavity located in the lower valve body.

- Shear Pin Mechanism: Fixed pins designed with a 5MPa shear strength.

- Spring Reset System: Restores initial state after pressure balancing.

2. Core Functional Components:

- Dual Sealing System: Primary seal (ball-to-seat) and secondary seal (enlarged chamber).

- Pressure-Triggered Mechanism: Overload protection via shear pins and springs.

- Check Valve Configuration: Forms a unidirectional flow path through ball and seat repositioning.

II. Working Principle

(A) Normal Closure Mode

1. Manual Operation:

- When overflow or blowout is detected, operators rotate the knob 90° clockwise using a wrench.

- The ball aligns fully with the valve seat, and the positioning surface contacts the fixed seat.

- A metal-to-metal hard seal is formed, completely blocking the mud flow path.

2. Pressure Isolation:

- Withstands bidirectional pressure in the closed state.

- Prevents upward transmission of formation pressure (up to 70MPa).

- Protects surface equipment (e.g., rotary hose, standpipe) from overpressure damage.

(B) Check Valve Mode (Overload Protection)

1. Activation Conditions:

- Forward pressure differential ≥5MPa (upper ball pressure minus lower pressure).

- Scenarios include:

- Post-closure jamming preventing manual reopening.

- Need for temporary circulation channels.

- Special well depth requirements for unidirectional flow.

2. Automatic Transition Process:

- Shear Pin Failure: Precision-engineered pins fracture at 5MPa differential.

- Component Downward Shift: The floating ball and movable seat compress the spring, moving downward 8–10mm.

- Seal Reconfiguration: The sealing section enters the enlarged chamber, creating an annular gap.

- Unidirectional Flow Path: Mud flows downward (fixed seat → movable seat) but reverse flow is blocked.

3. Functional Features:

- Maintains pressure balance while enabling controlled pressure relief.

- Prevents "pressure lock" post-closure.

- Provides a flow channel for subsequent well-killing operations.

This device employs a mechanical-hydraulic linkage design to ensure reliable pressure control under both routine and emergency conditions. As critical safety equipment for deep and ultra-deep wells, its innovative pressure-triggered mechanism reduces emergency response time by over 60% compared to traditional plug valves, significantly enhancing well control safety.