The Azimuthal Gamma Ray Sensor (Azimuthal GR Sub) is a critical component in Measurement While Drilling (MWD) or Logging While Drilling (LWD) systems. It plays a vital role in petroleum drilling, especially in the geosteering of directional wells, particularly horizontal and extended-reach wells. Its core function is to provide gamma ray intensity measurements of the formation with directional (azimuthal) information.

Here are its specific roles:

1. Identifying Formation Boundaries and Reservoir Limits (Core of Geosteering):

Detecting the Bit Position Relative to Formations: This is the most fundamental function of azimuthal GR. It not only measures the overall gamma ray intensity of the formation (reflecting rock radioactivity, commonly used to distinguish shales from reservoir rocks like sandstones/carbonates) but also discerns which direction (azimuth) has strong gamma rays and which has weak.

Determining if the Bit is Inside the Reservoir, Near the Top Boundary, or Near the Bottom Boundary:

When drilling a horizontal section within a reservoir, if the bit approaches the clay-rich caprock (top boundary, usually high GR), azimuthal GR will show a significant increase in gamma ray values from the top (high-side).

If the bit approaches the clay-rich base (bottom boundary, usually high GR), azimuthal GR will show a significant increase in gamma ray values from the bottom (low-side).

If the bit is in the middle of the reservoir, GR values from all directions will be relatively low and uniform.

Real-time Well Path Adjustment Guidance: Based on the directional information about formation boundaries (whether the top or bottom is getting closer), the geosteerer can instruct the directional driller in real-time to adjust the inclination angle (build or drop angle) to keep the bit traversing within the optimal position of the target reservoir (usually low GR), maximizing reservoir contact.

2. Distinguishing Formation Anisotropy:

Formation properties (like lithology, sedimentary structure) may differ between vertical and horizontal directions. Azimuthal GR can detect these directional differences. For example, when crossing dipping beds or thinly laminated formations, varying gamma responses from different directions help understand formation structure and dip.

3. Detecting Fractures and Faults:

Near fracture zones or small faults, gamma ray intensity may show anomalous variations due to fluid activity or mineral infill. Azimuthal GR helps locate the azimuth where these anomalies occur, providing information for geological interpretation and subsequent completion design (e.g., frac stage selection).

4. Lithology Identification and Correlation:

Provides finer lithological information than full-bore GR. By analyzing variations in GR values from different directions, it allows for more accurate identification of thin beds, interbeds, and complex lithological sequences, enabling more precise correlation with offset wells or geological models.

5. Improving Formation Evaluation Accuracy:

Directional measurements reduce the averaging effect of formation heterogeneity on the results, providing data closer to the true formation properties. This is particularly advantageous in thin beds or anisotropic formations compared to traditional full-bore GR logging.

6. Enhancing Wellbore Stability Monitoring (Indirectly):

By more precisely identifying the position of high-GR shale layers (often softer and prone to collapse), it can help predict and avoid potential complications while drilling through these unstable zones.

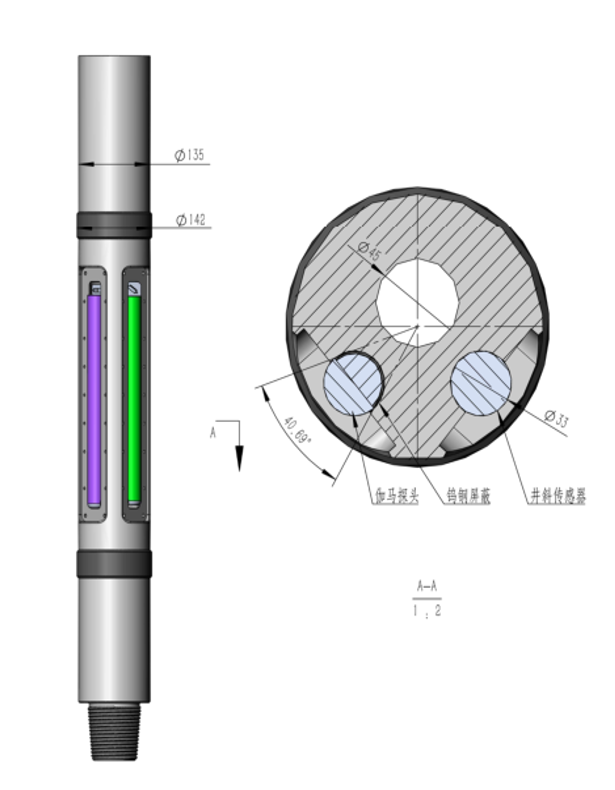

Brief Working Principle Description:

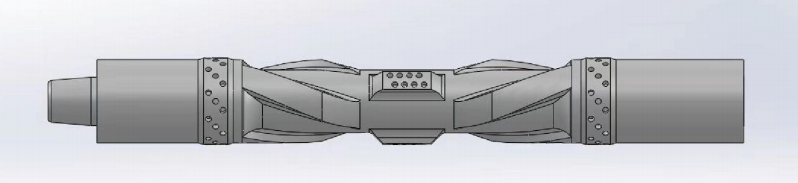

The azimuthal GR sub typically contains multiple gamma ray detectors (commonly 4, 6, 8, or 16) arranged circumferentially around the drill collar. When the Bottom Hole Assembly (BHA) is operating downhole:

Rotary Drilling: As the drillstring rotates, each detector scans different directions around the borehole circumference. The system records the count rate for each detector and combines it with precise magnetic or gravity toolface angle (azimuth) information to assign the measurements to different azimuthal sectors (e.g., every 45° or 30°). This ultimately generates a continuous image of gamma ray intensity distributed by azimuth (usually represented by a color scale, displayed along depth and borehole circumference).

Sliding Drilling (Directional Drilling): The drillstring does not rotate. The toolface angle is fixed, and the detectors face a fixed direction. GR intensity from a specific direction (e.g., high-side, low-side, left, right) can be directly read. This is the most crucial real-time data for geosteering, directly indicating the bit position relative to the top or bottom boundaries of the formation.

In summary, the core value of the azimuthal gamma ray measurement sub lies in:

Providing Directional Geological Information: This is its key distinction and advantage over traditional full-bore gamma ray logging.

Enabling Precise Geosteering: It is crucial technology for successfully drilling horizontal and extended-reach wells and maximizing reservoir contact area.

Improving Formation Evaluation Accuracy: It provides more detailed and less averaged descriptions of formation properties.

It essentially tells the drilling team in real-time: "Is the bit currently in the middle of the reservoir, about to drill into the shale above, or about to drill into the shale below?" This guides them on whether "to steer up a bit or steer down a bit," ensuring the well path stays within the "sweet spot" zone. This is essential for increasing well productivity and ultimate recovery.