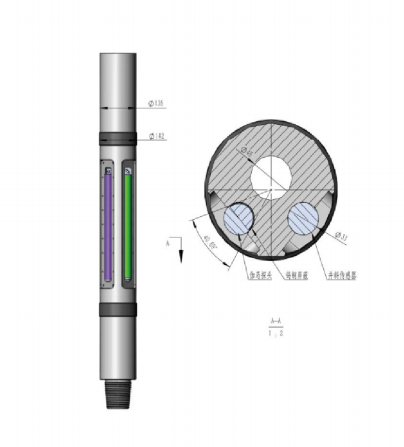

Core Function: Transmits real-time MWD/LWD data (inclination, azimuth, temperature, gamma, etc.) to surface via mud pulse telemetry in high-temperature/high-pressure (HTHP) downhole environments.

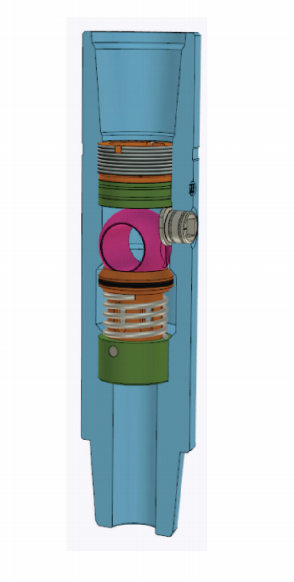

1.High-Temperature Adaptability

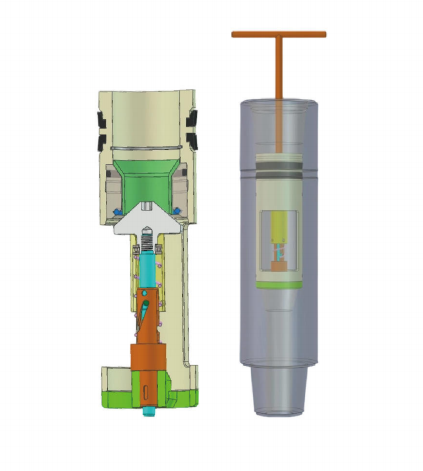

-Temperature Resistance >175°C: Uses specialty alloy valve bodies + high-temperature seals to prevent seal failure/electronic burnout in deep wells (geothermal gradient: 2.5-4°C/100m).

-Hydraulic Drive Advantage: Valve plate actuated by hydraulic pressure (not direct electronics), reducing heat damage to components.

2.Data Transmission Reliability

-Binary Encoding: Generates pressure pulses by rapidly shearing mud flow (e.g., open=1/closed=0) at 3-12 bit/s.

-Anti-Interference Design: Forcible mud shearing creates stronger signals vs. positive/negative pulsers (especially in high-density mud).

3.Risk Mitigation

-Real-Time Trajectory Control: Transmits inclination/azimuth data for precision steering (horizontal well TVD error <0.5m).

-Early Warning: Detects downhole vibrations/temperature spikes to prevent stuck pipe or tool failure.

4.Economic Benefits

-Reduced Tripping: Operates >200 hours under HTHP conditions, avoiding trips due to tool failure (~$150k/trip cost).

-Drilling Optimization: Enables "one-trip" drilling with geosteering, shortening cycle time by 20%-30%.

5.Applications

-Deep Formations: Shale gas (>4,000m TVD), HTHP gas reservoirs

-Extended-Reach Wells: Offshore platforms (reduces subsea wellhead adjustments)

-Sour Gas Wells: Compatible with sour-service alloys for H₂S resistance