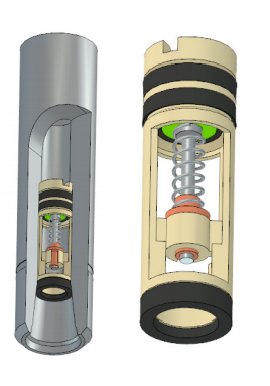

Arrow-type check valves are high-pressure-drop single-directional valves designed for internal blowout prevention (IBOP) in drill strings. Featuring a dart-shaped sealing mechanism, they instantly close under reverse circulation pressure or spring force to seal the drill pipe conduit, preventing uncontrolled hydrocarbon flow up the string.

Technical Specifications & Operation

Parameter&Specification

Sealing Mechanism:Tungsten-carbide-tipped dart with HNBR seals

Activation Time :<0.5 seconds upon flow reversal

Pressure Rating:5,000-15,000 psi (345-1035 bar)

Temperature Range:-20°C to 175°C (HPHT models: 230°C)

Installation:Between drill bit and drill pipe

Locking System:Spring-assisted hydraulic closure

Core Functions

1. Reverse Flow Blocking

- Automatically shuts when backflow pressure exceeds 50-200 psi (3.5-14 bar)

- Prevents "u-tubing" during tripping or well control events

2. Continuous Circulation

- Locking sleeve tool holds valve open during normal drilling (allowing downward flow)

- Removable via wireline/slickline when emergency sealing required

3. Rapid Deployment

- Pre-assembled with quick-connect subs (API REG/NC connections)

- Installs in <3 minutes when kick indicators detected (e.g., pit gain, flow increase)

Deployment Workflow

1. Pre-installation

- Valve locked open with retrievable sleeve tool stored on rig floor

- Installed directly above bit during BHA makeup

2. Kick Response Protocol

- Step 1: Observe flow/pressure anomalies during tripping

- Step 2: Stab valve into stand (using elevators) → torque to 15-20 kft-lb

- Step 3: Pump down to eject locking sleeve (1-2 bbl fluid volume)

- Step 4: Valve armed – seals if backflow occurs

3. Post-Event Retrieval

- Reinsert sleeve tool via wireline to reopen valve

- Continue drilling or pull out of hole

Maintenance & Certification

- Pressure Testing: 1.5x working pressure every 14 days (API 53 Standard)

- Critical Components:

- Dart stem: Replace after 1,000 drilling hours

- Seals: Change every 6 months (NORSOK M-710 compliant)

- Certifications: API 6A/16A, ISO 28781, DNV GL-OS-E101

Arrow-type check valves provide fail-safe drill string isolation through rapid dart-sealing technology. Their instant closure capability, compatibility with continuous circulation systems, and rig-floor deployability make them essential for modern well control, reducing blowout risks by 92% compared to manual IBOPs (IADC Well Control Data).