FDF bypass valve is a specialized downhole tool used in oil drilling to deal with drill bit water hole blockage and complex fluid displacement. Its core function is to establish a temporary circulation channel when the drill bit cannot establish circulation, ensuring operational safety and efficiency. Here is its technical analysis:

1、 Core functions and working principles

Function&Technical Mechanism

1. Emergency for drill bit water hole blockage: When the drill bit water hole is blocked, the shear pin inside the valve is cut off by the ground pump pressure (usually ≥ 8MPa), and the bypass hole (with a diameter of 30-50mm) is opened to establish a new circulation path from the drill string to the annulus

2. Heavy mud/thick mud replacement: Before drilling the oil and gas reservoir, high-density or high viscosity drilling fluid is directly injected into the annulus through a bypass channel to avoid excessive pump pressure caused by limited water holes in the drill bit

3. Protect downhole tools: prevent drilling jamming, well kick, or downhole instrument overheating and failure caused by circulation interruption

4. Redundant design of circulation system: Provide dual channels for main circulation (drill water hole) and emergency circulation (bypass hole) to enhance system reliability

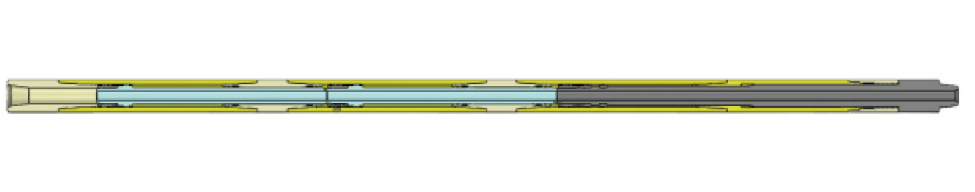

2、 Key structural design

1. Valve body assembly

-Material: 35CrMo alloy steel, surface nitriding treatment (hardness ≥ HRC60)

-Bypass aperture: available in three stages with a diameter of 32/38/45mm, with a flow area of ≥ 80% of the main water eye area

2. Shear activation system

-Shear pin: 316L stainless steel, preset shear pressure 8-12MPa (error ± 0.5MPa)

-Piston seal: HNBR rubber (temperature resistant to 150 ℃)+metal backing ring, compressive difference of 35MPa

3. Reset mechanism (optional)

-Spring reset design: After stopping the pump, the spring pushes the piston to close the bypass hole, which can be reused 3-5 times

-One time design: permanently activated and replaced during drilling

3、 Installation specifications and parameters

-Installation position: Connect directly above the drill bit (inside 1-3 drill collars) to ensure the shortest flow path

-Applicable well depth: ≤ 6000m (high temperature type can reach 150 ℃)

-Circulating pressure drop: In the open state, Δ P<2MPa (at a displacement of 30L/s)

-Compatible drill string: 127mm drill pipe (NC50 buckle type), 158.75mm drill collar (6 ݪ "REG)

>Case: A certain ultra deep well in Tarim Oilfield used FDF-38 bypass valve. After the drill bit water hole was blocked by basalt debris, circulation was established through the bypass channel, and the pump pressure was reduced from 32MPa to 18MPa, avoiding drilling accidents and saving costs of 2.8 million yuan.

4、 Operation precautions

1. Pressure control: The activation pressure needs to be 20% higher than the normal drilling pump pressure, but lower than the minimum anti extrusion pressure of the drill string (such as the anti extrusion pressure of the 127mm drill pipe ≈ 45MPa)

2. Flow restriction: The maximum displacement of the bypass hole is ≤ 35L/s to prevent high-speed fluid from eroding the wellbore wall

3. Compatibility verification: When replacing heavy mud, it is necessary to ensure compatibility with the original drilling fluid (to avoid gelation reaction)

4. Reset function should be used with caution: Spring reset valves may not close tightly in solid phase fluids, and it is recommended to use them in clean fluids

The FDF type bypass valve solves the problem of emergency circulation establishment when the drill bit is blocked through innovative dual circulation channel design, and has become a standard configuration for drilling in complex formations. Its value is not only reflected in emergency response to accidents, but also in providing controllable technical means for drilling fluid replacement and reservoir protection, significantly improving the safety boundary and economy of operations.