Ceramic Float Valve: Revolutionizing Drill String Check Valve Performance

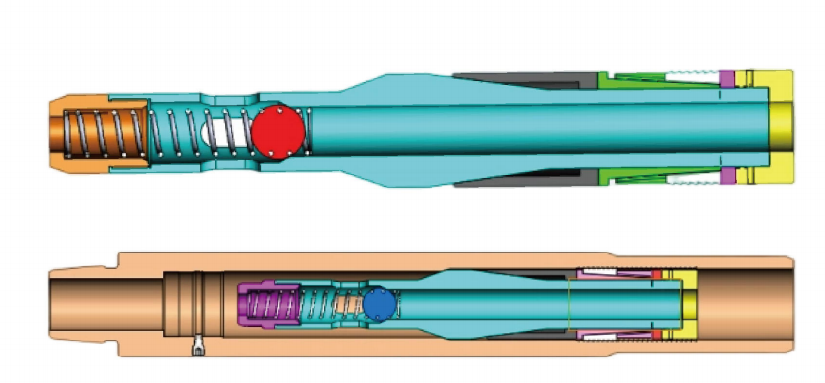

The Erosion Failure Challenge in Conventional Float Valves

Traditional metal float valves suffer from:

-Rapid erosion failure in abrasive drilling fluids → 50-100 hour lifespan

-Unreliable sealing after minimal wear → well control risks

-Frequent replacements costing $20K+/valve in downtime and parts

Our ceramic float valve delivers:

✅ 10x longer service life through erosion-resistant ceramics

✅ Zero leakage sealing even after extended use

✅ API 7-1 certification for reliable well control

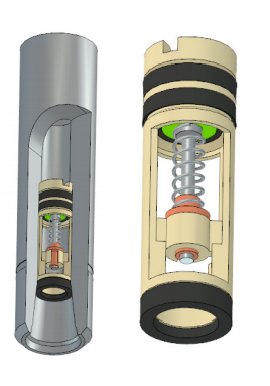

Ceramic Technology Breakthrough

Silicon Nitride Valve Core Advantages | ||

Property | Steel Valve Core | Ceramic Valve Core |

Hardness | HRC 58-62 | HRA 90-92 (Approaching diamond hardness) |

Erosion Resistance | 1x (baseline) | 10x improvement |

Service Life | 50-100 hours | 500-1,000 hours |

Corrosion Resistance | Moderate | Excellent in H₂S/CO₂ environments |

→ Full-density silicon nitride manufactured by hot isostatic pressing

→ Polished to Ra 0.2μm surface finish for perfect sealing

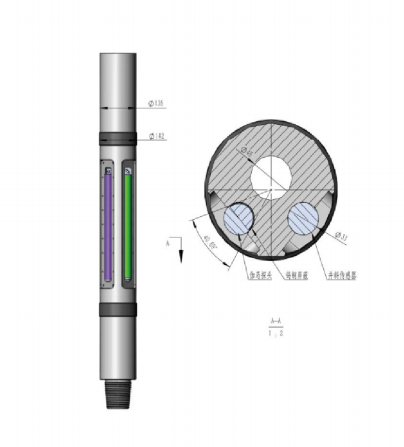

Technical Specifications

Parameter | Specification |

Pressure Rating | 5,000psi / 10,000psi options |

Temperature Rating | -50°C to 250°C |

Valve Core Material | Silicon nitride (Si₃N₄) |

Body Material | 4145HM steel with corrosion-resistant coating |

Seal Type | Ceramic-to-metal primary seal |

Connections | API REG, IF, FH (all standard sizes) |

Certifications | API Spec 7-1, NACE MR0175, ISO 9001:2015 |

Operational Benefits

-Extended Service Life

500+ hours continuous operation in abrasive mud systems

10x reduction in replacement frequency versus steel valves

-Enhanced Reliability

Zero failures due to erosion in field testing

Consistent sealing performance throughout service life

-Economic Value

$150K+ savings/well in reduced downtime and replacement costs

Eliminate unexpected failures during critical operations

Field Applications

Abrasive Drilling Environments: Sandstone, shale, and other abrasive formations

High-Temperature Wells: 250°C capability for geothermal and HPHT applications

Sour Gas Operations: Excellent corrosion resistance in H₂S environments

Deepwater Drilling: Reliable performance in critical narrow-margin applications

Extended Reach Drilling: Long-life performance for marathon drilling operations