The working principle of the oil drilling injection oil float valve involves several key mechanical and fluid dynamics principles:

1. **Fluid Pressure Control**:

- The injection oil float valve operates by maintaining a constant level of fluid in the wellbore, preventing fluid overflow or deficiency. This valve is typically installed in the production casing or tubing and is activated by the pressure difference between the wellbore and the annular space.

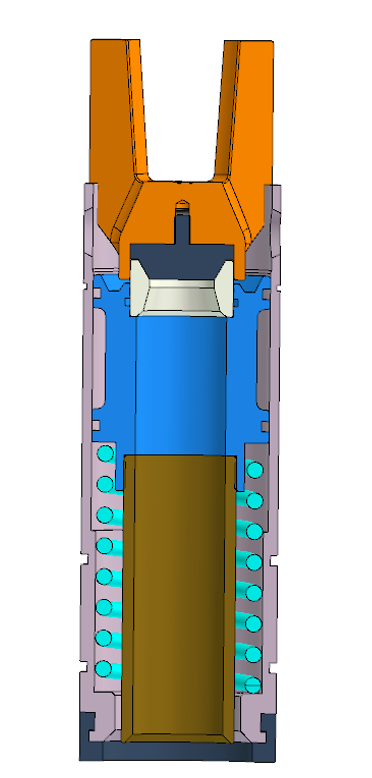

2. **Valve Disc Action Mechanism**:

- In the injection oil float valve, the valve disc (also known as the flap) is a key component that opens or closes in response to changes in pressure within the wellbore. When the pressure inside the wellbore exceeds the pressure in the annular space, the valve disc closes to prevent fluid backflow into the well. Conversely, when the pressure inside the wellbore decreases, the valve disc opens, allowing fluid to flow into the well.

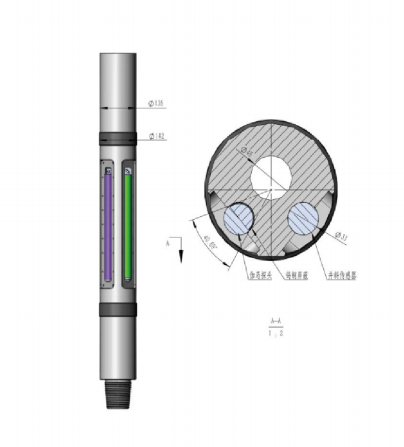

3. **Pressure Regulation**:

- The injection oil float valve controls and regulates the pressure of the lubricating oil through a pressure regulating valve. After the lubricating oil is pushed out by the pump, the pressure regulating valve can adjust the pressure of the lubricating oil as needed, ensuring that the lubricating oil is delivered to the areas requiring lubrication at the appropriate pressure for optimal lubrication effects.

4. **Oil Tank and Oil Pipeline**:

- The oil tank of the injector serves to store lubricating oil, while the oil pipeline transports the lubricating oil from the tank to the areas that require lubrication. The oil pipeline needs to have sufficient pressure resistance and wear resistance to ensure smooth delivery of lubricating oil.

5. **Automatic Control**:

- The injection oil float valve can automatically adjust according to downhole conditions to maintain a balance of downhole pressure. This automatic control mechanism helps reduce the risk of blowouts and enhances the safety of drilling operations.

6. **Blowout Prevention**:

- The injection oil float valve also plays a crucial role in preventing blowouts. When the pressure inside the wellbore exceeds a certain threshold, the float valve automatically closes to prevent blowouts, protecting personnel and equipment from potential harm.

In summary, the working principle of the oil drilling injection oil float valve is to automatically regulate the level of fluid in the wellbore and control fluid flow to optimize drilling efficiency and safety.