The working principle of a hydraulic thruster primarily involves converting the kinetic energy of high-pressure drilling fluid into mechanical thrust to propel the drill bit for drilling. Here is the specific working principle:

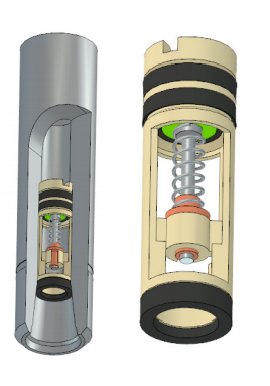

1. **Energy Conversion**:

- The hydraulic thruster converts the kinetic energy of high-pressure drilling fluid into axial thrust of multi-stage pistons. This thrust is used to push the drill bit, achieving pre-fracturing of the rock.

2. **Thrust Generation**:

- When high-pressure drilling fluid flows through the lower drill bit nozzle or downhole motor of the thruster, the pressure drop generated acts on the multi-stage pistons, pushing them downward to apply drilling pressure.

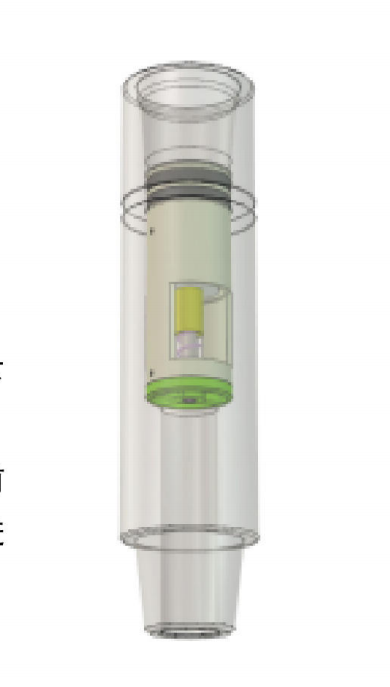

3. **Structural Composition**:

- The hydraulic thruster typically consists of an upper joint, pistons, cylinder, and core shaft. These components work together to effectively convert fluid power into mechanical thrust.

4. **Flexible Pressurization**:

- Compared to traditional rigid pressurization methods, the hydraulic thruster can achieve constant and uniform drilling pressure. This flexible pressurization method can increase mechanical drilling speed and reduce drill string fatigue failure.

5. **Reducing Vibration**:

- By absorbing drill string vibration and drill bit impact, the hydraulic thruster can reduce axial vibration of the drill string. This helps protect the drill string and drill bit, extending their service life.

Through these mechanisms, the hydraulic thruster effectively improves drilling efficiency and the service life of drilling tools, while reducing complexities and risks in the drilling process.