The working principle of a hydraulic oscillator is primarily based on the combination of fluid dynamics and mechanical vibration. Here is the basic working principle:

1. **Fluid Drive**:

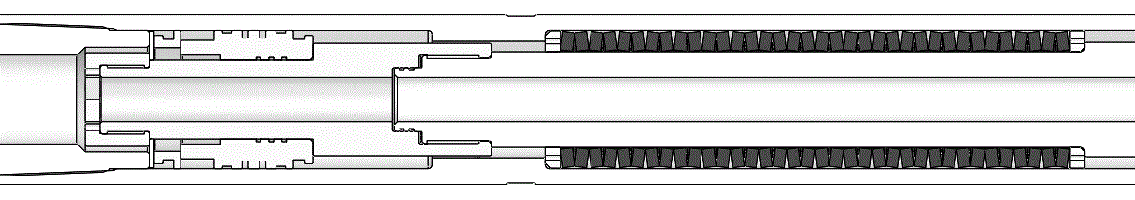

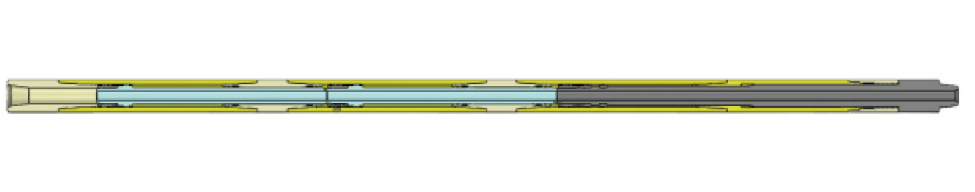

- Drilling fluid passes through the power section of the oscillator, typically a turbine or motor, which drives the internal rotor to rotate. This rotational motion is transmitted through mechanical connections to other parts of the oscillator.

2. **Pressure Pulse Generation**:

- Inside the oscillator, fluid flows through a series of valves and channels, creating periodic pressure changes. The opening and closing actions of these valves alter the fluid flow path and pressure, generating pressure pulses within the oscillator.

3. **Mechanical Vibration**:

- The pressure pulses act on the oscillator's spring or piston system, causing it to move reciprocally. This reciprocating motion is converted into mechanical vibration, which is transmitted to the connected drilling tools.

4. **Friction Force Transformation**:

- By generating axial vibration, the hydraulic oscillator transforms the static friction between the drilling tools and the wellbore into dynamic friction, significantly reducing frictional resistance. This helps improve the effective transmission of drilling pressure and drilling efficiency.

5. **Energy Conversion**:

- The oscillator converts the hydraulic energy of the fluid into mechanical energy, using vibration to enhance the performance and efficiency of the drilling tools.

6. **Frequency and Amplitude Control**:

- The vibration frequency and amplitude of the oscillator can be controlled by adjusting the fluid flow rate and the settings of the internal valves to adapt to different drilling conditions.

Hydraulic oscillators effectively reduce friction between drilling tools and the wellbore, improving drilling speed and efficiency while reducing the risk of tool wear and drilling accidents.