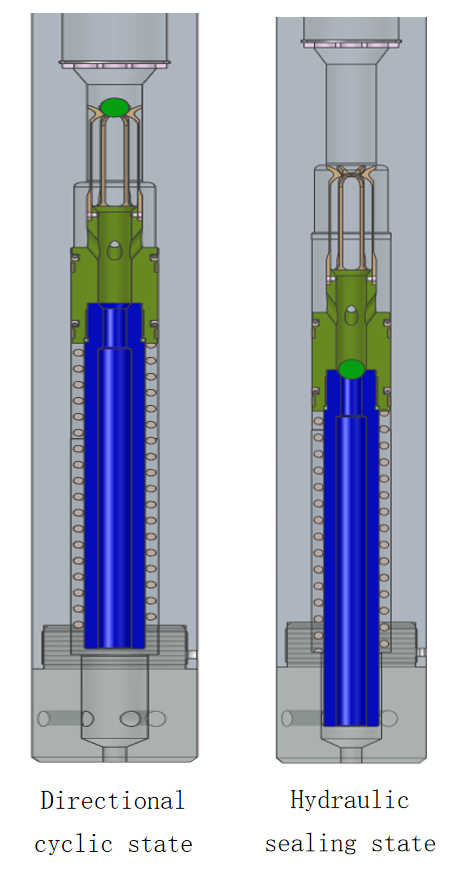

1. Orientation Circulation State

- Workflow:

- The mud pump circulates drilling fluid downhole, which flows smoothly through the internal flow channel of the whipstock.

- Hydraulic pressure remains balanced at low levels, maintaining all components (slips, springs, orientation mechanism) in their initial positions.

- Purpose:

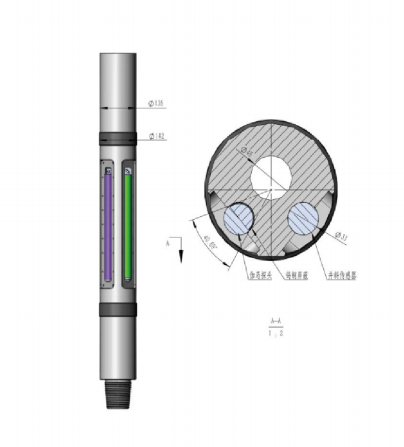

- Ensures precise alignment of the whipstock face with the target formation (accuracy ≤±1°).

- Prevents premature activation of the anchoring system.

2. Hydraulic Sealing State

- Activation: Increase mud pump flow rate to threshold (typically ≥800 L/min) after orientation.

- Workflow:

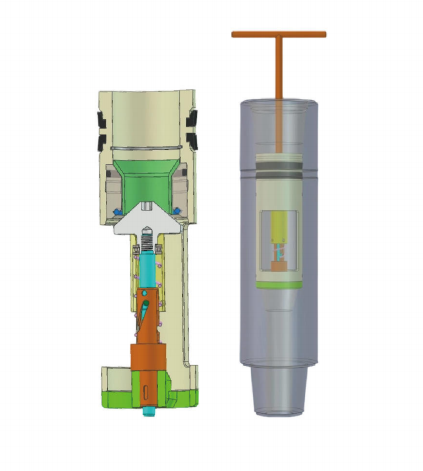

1. High-Flow Activation: Drilling fluid drives the sealing ball and expandable ball seat carrier downward.

2. Carrier Expansion:

- The carrier radially expands (200% diameter increase) upon reaching the lower chamber, locking against its shoulder.

- Material: Nitinol frame + oil-resistant rubber.

3. Ball Seating:

- The sealing ball seats onto a metal-to-metal seal at the bottom sub.

- Blocks internal flow (pressure rating ≥15,000 psi).

- Confirmation:

- Sudden pressure spike detected at surface confirms successful sealing.

- Triggers subsequent anchoring/window-cutting procedures.

Key Parameters

- Flow Threshold: 800–1,200 L/min (adjustable for hole size)

- Temperature Resistance: -40°C to 175°C

- Sealing Response Time: <30 seconds

- Reusability: ≥5 wells

Operational Workflow

1. Run in hole to target depth.

2. Orientation State: Circulate mud + calibrate azimuth with wireless gyro.

3. Sealing State: Increase flow to trigger ball-carrier expansion and flow path sealing.

4. Confirm sealing via pressure spike.

5. Set anchor by slacking off weight to shear pins.

6. Initiate cutting with mill assembly.

Case Study

- Well Conditions: Bohai Sea, Ø244.5mm casing at 3,200m MD.

- Results:

- Anchor set in 1.2 hrs (vs. 4 hrs conventionally).

- Window smoothness allowed Ø120mm BHA pass-through.

- $18,000 USD saved per run.

Core Innovations

- Fail-Safe Hydraulic Switching: Eliminates manual intervention using flow-rate automation.

- Metal Sealing: Ensures zero leakage in HP/HT environments.

- Self-Confirming Mechanism: Pressure spike provides real-time operational certainty.

- Industry Impact: Reduces side-tracking time by 60% while enhancing reliability in complex wells.