1. Convert hydraulic energy of drilling fluid into mechanical energy (core power conversion):

This is the most fundamental and important function of screw drilling tools.

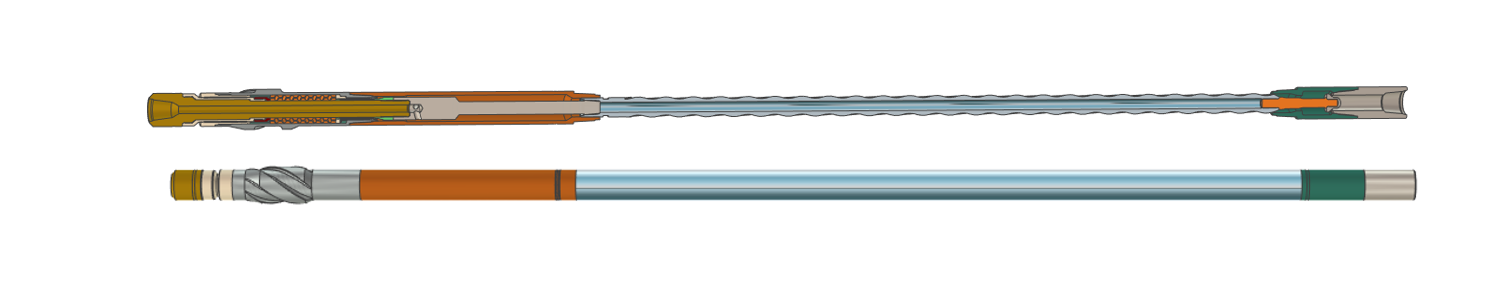

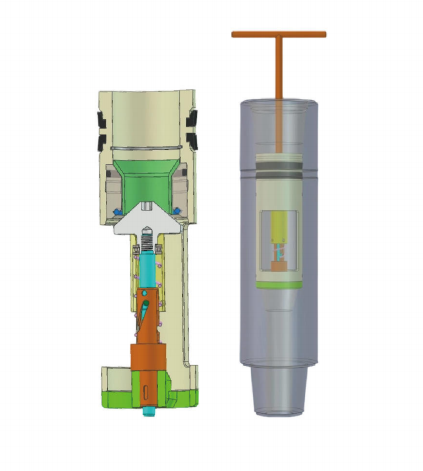

Working process: High pressure drilling fluid is pumped into the wellbore through the drill string and flows through the sealed chamber composed of the stator and rotor inside the screw drilling tool.

Energy Conversion: The hydraulic energy (pressure and flow) of drilling fluid drives the rotor to perform planetary motion (eccentric rotation) inside the stator, thereby directly converting the energy of the fluid into the rotational mechanical energy of the drive shaft.

Power output: The drive shaft directly transmits the rotational torque to the drill bit.

2. Provide direct rotational power to the drill bit:

Derived directly from Function 1.

The core function of a screw drill is to drive the drill bit to rotate and perform rock breaking drilling.

Key advantages: This power transmission method is direct (from the drilling tool to the drill bit), localized (generated near the drill bit), and efficient (with relatively low energy loss).

3. Achieve directional drilling and precise trajectory control:

This is an irreplaceable key application of screw drilling tools in modern drilling.

Bent Shell/Adjustable Bent Shell: Most directional screw drilling tools come with fixed or adjustable angled shells.

Sliding drilling: In the "sliding drilling" mode of directional operation, the entire drill string (including the drill collar) does not rotate, only the drill bit rotates under the drive of the screw drill. At this point, the bending angle on the drilling tool will cause the drill bit to deviate from the centerline of the wellbore and drill in a specific direction.

Trajectory control: By adjusting the tool face angle (the direction pointed by the curved shell), the direction of the wellbore's advance in the vertical and horizontal planes (inclination angle and azimuth angle) can be precisely controlled, allowing the wellbore to extend along the designed trajectory.

4. Improve drilling efficiency and speed:

Direct drive, efficient energy transfer: Compared to the traditional method of relying on the ground turntable to transmit rotation through several kilometers of drill string, screw drilling tools directly drive the drill bit at the bottom of the well, reducing energy loss during long-distance transmission (such as drill string torsion, vibration, friction), and more energy is directly used for rock breaking, significantly improving mechanical drilling speed.

Reduce drill string rotation (sliding drilling): During directional sliding drilling, it avoids the rotational friction between the entire drill string and the wellbore wall, reduces torque and friction , reduces drill string wear and fatigue, and reduces the risk of drilling jamming.

Composite drilling: Even when rotating the drill string (composite drilling) is required, the additional rotational speed provided by the screw drilling tool can further increase the drilling speed.

Summary

The core value of screw drilling tools lies in their underground power conversion ability, which brings two revolutionary advantages:

1. Directional ability: Accurate wellbore trajectory control is achieved through the "sliding drilling" mode.

2. Efficiency improvement: By directly and efficiently driving the wellbore, the rock breaking efficiency and drilling speed are significantly improved, while reducing some operational risks (such as drill string wear and high torque).