I. Enhanced Material Selection & Manufacturing Process

1. High-Strength Base Material

- Main body constructed from 304/316L stainless steel, refined through vacuum degassing to ensure material purity and minimize stress concentration risks from impurities.

- Critical pressure-bearing zones undergo localized induction hardening, achieving surface hardness of HRC 45-50 while retaining a tough core hardness of HB 280-320 for impact-resistant "hard exterior, tough core" performance.

2. Monolithic Precision Forming Technology

- Manufactured via forging + CNC precision machining:

- Forging eliminates internal voids and enhances metal grain continuity;

- CNC machining ensures transition radii ≥R5mm at tapered surfaces to prevent stress cracking;

- Internal bore surface roughness controlled to Ra≤1.6μm, reducing turbulent flow friction.

---

II. Structural Innovation Analysis

1. Thickened Wall Design

- Wall thickness increased by 40%-60% versus conventional products (e.g., from 8mm to 12-13mm), improving collapse resistance by ≥35%;

- Features axial wall thickness gradient (thickest at inlet, progressively thinning toward outlet) to balance weight and wear resistance in high-sand-content formations or high-flow-rate drilling fluid conditions.

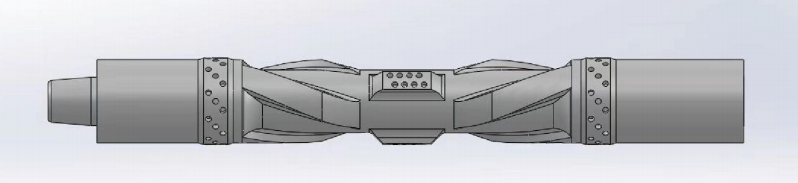

2. Tapered Body Erosion-Resistant Structure

- 12°-15° taper angle:

- Low-angle taper guides fluid smoothly, reducing direct impact on straight sections;

- Compound radius transition at taper-straight junctions dissipates vortex energy;

- Tested performance: Reduces erosion rate by 62% in slurry with 15% quartz sand at 3m/s flow velocity.

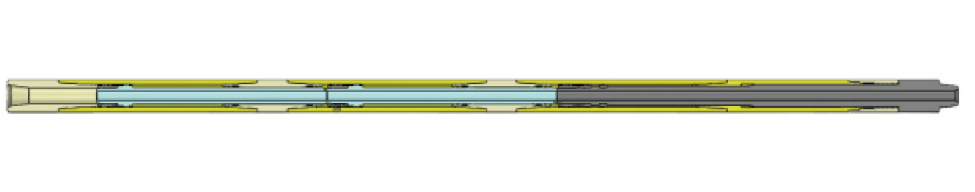

3. Long-Hole Flow Channel Hydrodynamic Optimization

- Aperture design:

- Oblong slots (8-10mm width × 30-40mm length) replace round holes, with aspect ratio 3:1-4:1;

- Channels angled at 22°-25° tangentially to induce helical fluid motion;

- CFD-verified results:

- Flow distribution standard deviation reduced by 48%, eliminating localized high-velocity jets;

- Peak wall shear stress decreased by 55%, significantly suppressing erosion.

---

III. Expanded Application Scope

1. Extreme Condition Adaptability

- Ultra-deep wells: Thickened walls ensure collapse resistance (≥8,000m depth);

- Shale gas lateral sections: Long-hole flow channels inhibit cuttings bed accumulation, reducing stuck pipe risk;

- Offshore drilling: 316L stainless steel resists chloride corrosion, compliant with NACE MR0175.

2. Economic Benefits

- Reduces filter replacements by 3-4 runs/well, saving 8-12 hours rig time/well;

- Lowers lifecycle maintenance costs by 40% (spares + labor).

---

IV. Maintenance Optimization

- Modular cartridge (if applicable):

- Quick-release latch system enables ≤15-minute replacement;

- Laser-etched material batch + service life QR code for precise maintenance;

- Monolithic construction:

- Provides ultrasonic thickness measurement reference surfaces for in-field wear monitoring.

---