Dual Anchor Hydraulic Whipstock is a key tool used in oil drilling for precise window opening and lateral drilling. Its function is to guide the drill bit to drill a new branch wellbore through the coordinated control of mechanical and hydraulic forces by opening windows in the casing or open hole section in a directional manner. The following is a detailed explanation of its core function and technical principles:

1. Core Role

(1)Precise directional window opening

-Cut a regular window (usually 3-6 meters in length) on the existing casing to provide a pathway for sidetracking a new wellbore.

-The inclined angle of the inclinometer (usually 45 ° -60 °) precisely controls the direction of the window opening, with an error of ≤± 1.5 °.

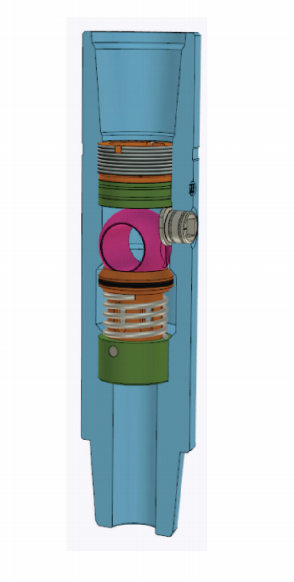

(2)Bi directional anchoring stability

- Anchor system : Resists the upward force generated by drilling pressure (WOB) and prevents the tool from moving up.

-Anchoring system: Resists torque and vibration, preventing tool rotation or falling.

-The bi-directional anchoring force can reach 50-80 tons, ensuring absolute fixation of the tool during the window opening process.

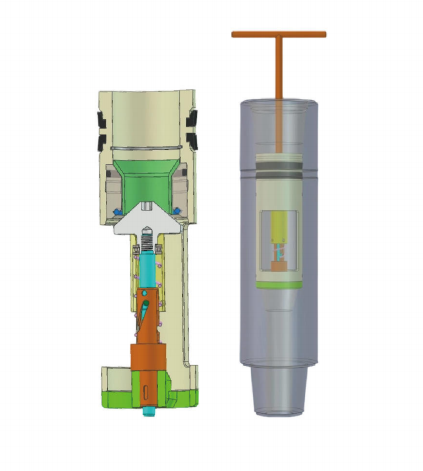

(3)Hydraulic controllability

-Activate the anchoring and setting mechanism through drilling fluid pressure (usually 10-20 MPa ) without the need for drilling adjustment.

-After opening the window, the anchor can be released hydraulically and the tool can be retrieved (some designs allow it to be left underground).

2. Key technological innovation

(1)Composite anchoring slip

-Tungsten carbide hard alloy teeth+elastic metal matrix, suitable for irregular wellbore walls.

-Adaptive expansion design, suitable for use in pipes with a diameter of 219-245mm.

(2)Hydraulic synchronization system

-The dual piston linkage structure ensures that the upper and lower anchors are seated simultaneously.

-The pressure balance valve prevents over sealing from causing damage to the slip.

(3)Disposable oblique surface

-The high-strength aluminum alloy inclined surface (compressive strength ≥ 800MPa) can be separated from the anchoring assembly.

-Reduce recycling risks, especially suitable for deep and ultra deep wells.

3. Application Scenarios

(1)Side drilling of old wells : Opening windows above depleted oil layers to develop new reservoirs.

(2)Obstacle drilling : Avoid fishing or complex geological fault areas underground.

(3)Multi branch well : Drill multiple branch wells in the main wellbore (TAML Level 3-4).

(4) Accident well rescue : Open a window above the stuck drilling point to resume drilling.

>Industry Trend: The global hydraulic inclinometer market reached $120 million in 2023, with an annual growth rate of 8.5% (data source: Spears&Assoc). Its high precision and efficiency are driving the development of directional well technology towards intelligence and integration.

4. Risk Control

- Anchor Failure Prevention : Clean the wellbore before sealing (sand content<0.5%) to avoid sand settling affecting the slip bite.

-Control of casing damage: Strictly monitor torque fluctuations during the milling stage (Δ T<20% is normal).

- Hydraulic system redundancy : Dual channel pressure transmission design, single channel failure can still be set/unsealed.

The bidirectional anchoring hydraulic inclinometer has become an irreplaceable tool for modern directional drilling through its three core capabilities of precise anchoring, efficient window opening, and controllable recovery. It significantly improves operational efficiency, especially in high value-added wells and complex structural wells.