Core objective: To achieve efficient opening of casing windows and support lateral drilling operations.

Workflow

1. Directional positioning

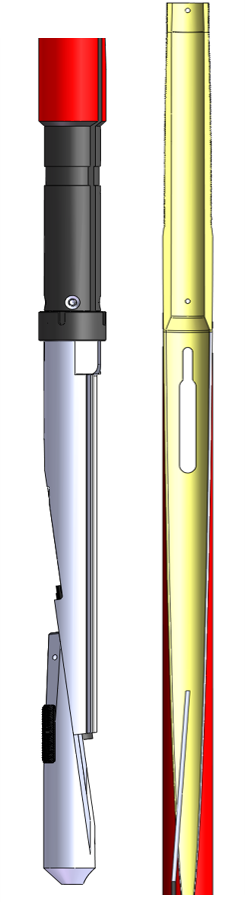

-After the tool is lowered to the predetermined well depth, it is designed in the same direction as the inclined surface of the inclinometer through the directional key inside the feed rod, combined with SST (single point inclinometer) or gyroscope for directional measurement to ensure accurate alignment of the inclined surface with the window orientation.

2. Hydraulic activation anchoring

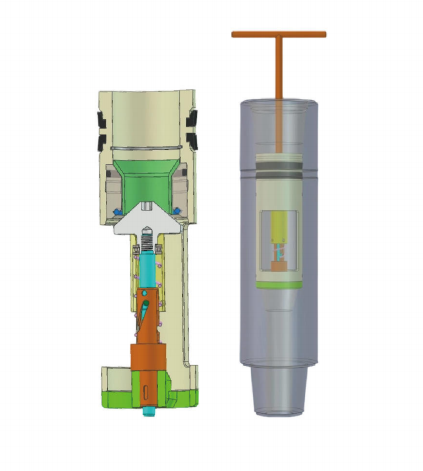

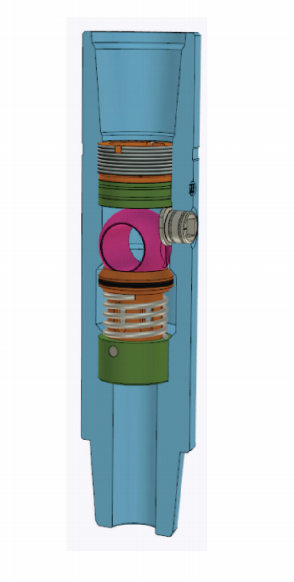

-Start the pump to build pressure: The drilling fluid transmits pressure through the pressure transmission pipe on the back of the inclinometer, pushing the piston of the hydraulic control system downwards.

- Shear release : The piston drives the pressure transmission rod, cuts the shear sleeve pin , and triggers the suspension mechanism.

-Kava anchoring: The spring compression force pushes the card tile upwards to contact the casing wall, generating a radial compression force to preliminarily fix the tool.

3. Mechanical seat hanging

- Lower the drill string and apply pressure : The drill string gravity cuts off the escort screw , forcing the slip to bite into the casing wall, completing the final anchoring (anchoring force can reach 50-80 tons).

4. One trip to drill through the window

-The inclinometer is directly connected to the compound milling cone (including the starting milling cone and the window milling cone) through the escort pin .

-Directly start rotary drilling after anchoring:

- Start milling cone Cut the casing under the guidance of the inclined plane.

- Window milling cone Expand the window and trim the edges.

-Complete the entire process of "sitting, hanging, opening windows, and repairing windows" in a single drill.

Key parameters

- Directional accuracy : Slope azimuth error ≤± 1.5 °

-Anchor pressure: Hydraulic activation pressure 8-12 MPa

- Shear Value Design :

-Pin shear force: 15-20 kN

-Escort screw shear force: 30-50 kN

-Temperature/Pressure Tolerance: 150 ° C/10000 psi

Application scenarios

-Sidedrilling of old wells: bypassing damaged sections or developing new layers.

-Branch wellbore: Drill multiple branches by opening windows on the main casing.

-Rescue of accident well: Drill from the side of the original wellbore to avoid falling fish.

Case : A platform in Beihai used an integrated inclinometer to open a window in a 244.5mm casing during a single drill run, saving 37 hours of operation time. The smoothness of the window met the requirement for a 9.5 "drill bit to pass through.

Summary

The integrated inclinometer achieves precise positioning and reliable fixation through a combination of directional keys, hydraulic anchoring, and mechanical suspension. Combined with a compound milling cone linkage design, it compresses traditional multi pass operations into a single pass. Its core value lies in:

1. Efficiency improvement : reduces the number of trips and shortens the window opening cycle by more than 60%;

2. Cost optimization : Single operation saves drilling fluid, drilling rig time, and labor costs;

3. Risk Control : Built in directional mechanism reduces calibration failure rate, hydraulic mechanical dual stage anchoring ensures stability of the suspension.

This technology has become the standard solution for modern and efficient side drilling operations.