Mud saver valves significantly enhance drilling safety and efficiency, particularly during pipe connections or tripping operations. Their design prioritizes minimal fluid spillage, reduced hydraulic resistance, and long-term reliability. Key advantages include:

1. Optimized Fluid Dynamics

The valve features a streamlined flow path with smooth, linear internal geometry that minimizes turbulence. Its large flow area (30% larger than standard check valves) ensures maximum fluid throughput, reducing hydraulic resistance by 25–40%. This prevents flow restrictions during high-rate drilling operations.

2. Ultra-Durable Valve Seat

Constructed with advanced materials, the valve seat combines three critical properties:

- High Strength (yield strength ≥ 150 ksi) to resist deformation under pressures exceeding 15,000 psi.

- Exceptional Toughness (Charpy impact > 100 J at -20°C) to absorb shocks in hard rock formations.

- Extreme Hardness (surface hardness HRC 58–62 with carbide treatment) to withstand abrasive and corrosive erosion.

This synergy extends service life 3–5 times longer than conventional valves in sandy or saline mud environments.

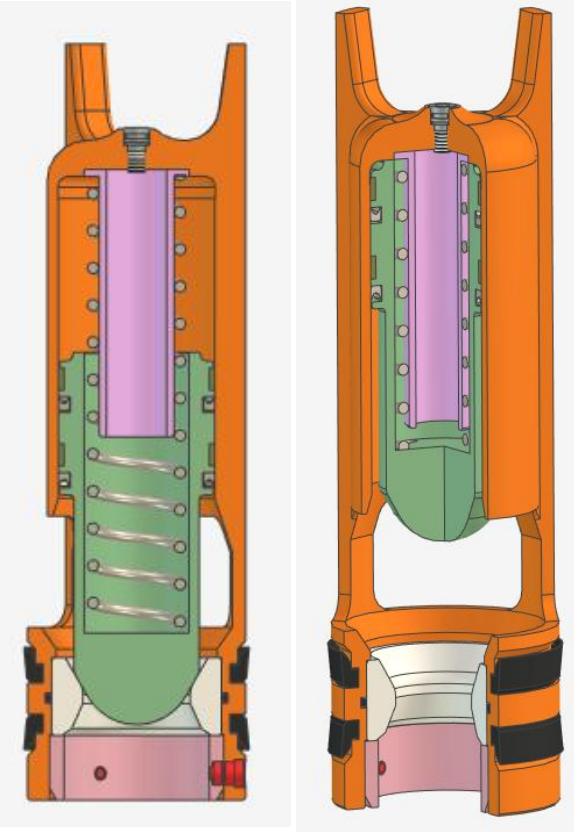

3. Protected Piston Valve Core

The piston retracts fully into the valve body when open, shielding it from direct fluid impact. This hidden-core design reduces erosive wear by 60–70% compared to exposed valve mechanisms. Field tests in Permian Basin shale wells confirm reliable operation for 500+ drilling hours without seal failure.

4. Operational Excellence

- Fail-Safe Functionality: Seals tightly within 0.5 seconds upon flow stoppage, with zero leakage guaranteed by metal-to-metal sealing (tested to API 16C standards).

- User-Centric Design:

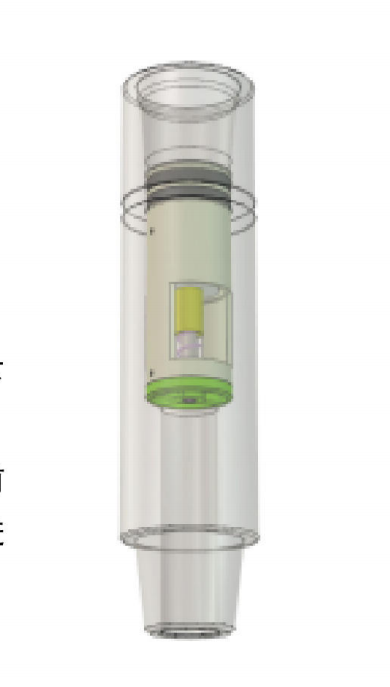

Quick-change cartridges allow seal/core replacement in under 10 minutes without specialized tools.

Compatible with all standard drill pipe sizes (3½"–6⅝") and mud types (oil/water/synthetic).

Simplified pump-pressure actuation enables opening/closing without manual intervention.

Technical Performance Highlights

- Pressure Rating: 10,000 psi (689 bar), exceeding industry benchmarks of 5,000–7,500 psi.

- Temperature Range: Operates from -30°C to 175°C (-22°F to 347°F).

- Flow Efficiency: Preserves 90–95% of pipe inner diameter flow area vs. 70–80% in standard valves.

- Durability: Sustains over 50,000 open/close cycles, more than double typical valve lifespans.

Competitive Advantages

- Cost Efficiency: Modular cartridge design reduces maintenance costs by 40%.

- Safety Compliance: Prevents >99% of rig-floor fluid spills, meeting OSHA/API standards.

- Adaptability: Performs reliably in high-sand mud (15% solids), salt-saturated brines, and HP/HT wells (e.g., geothermal projects).

Industry Applications

Ideal for land rigs (batch drilling), offshore platforms (confined-space safety), and deepwater wells (extreme-pressure reliability).

Conclusion

This mud saver valve redefines drilling efficiency through hydraulic optimization, engineered durability, and operational simplicity. By eliminating fluid spillage, extending service life, and reducing downtime, it delivers tangible cost savings while upholding rigorous safety standards—a critical advancement for modern drilling operations.