The Remote-Control Adjustable-Diameter Stabilizer (RCADS) excels in technological innovation and operational efficiency, offering significant advantages over conventional stabilizers. Below is a detailed analysis of its advanced features:

I. Structural Innovations

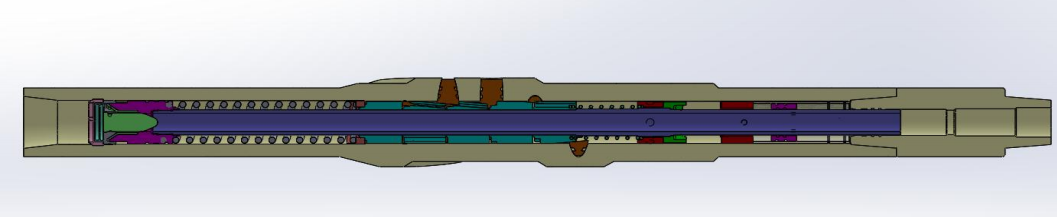

1. Monolithic Shell Design:

- Integrated Construction: Eliminates assembly joints, enhancing structural rigidity and reliability.

- High Strength-to-Weight Ratio: Withstands downhole stresses (e.g., shocks, vibrations) in complex formations.

- Easy Installation/Removal: Simplified connections reduce tripping time by 15–20%.

- Superior Sealing: Hermetic sealing prevents fluid ingress, extending service life.

2. Patented Retractable Piston System:

- 12–15 Pistons: Optimized radial coverage for maximum wall contact.

- Cylindrical-Arc Surface:

- Increases contact area with the wellbore by 30–40% vs. traditional designs.

- Enhances centralization accuracy, reducing well deviation by ≤0.5°/30m.

- Anti-Drop & Wear Resistance:

- Pistons feature interlocking grooves and tungsten carbide coatings (HV ≥1,100).

- Operational lifespan exceeds 1,500 hours in abrasive formations.

II. Intelligent Control System

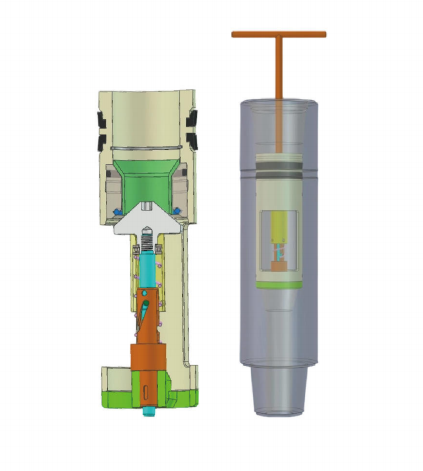

1. Pump-Actuated Directional Control:

- Mechanism: Surface pump cycles (start/stop) trigger downhole hydraulic valve shifts.

- Advantages:

- Eliminates complex electronics vulnerable to downhole conditions (HT/HP/vibrations).

- Reduces failure rates by >60% compared to electronic RCADS.

- Operators control diameter changes without downlink signals.

2. Mushroom-Head Signal Monitoring:

- Real-Time Feedback: Surface pressure/torque sensors detect piston extension/retraction status.

- Fail-Safe Alerts: Instant notification of malfunction (e.g., incomplete deployment).

III. Field Applications

- Directional Drilling: Maintains precise trajectory in S-shaped or horizontal wells.

- Unstable Formations: Prevents wall collapse in shale/sandstone by reducing vibration.

- Deepwater/HPHT Wells: Operates reliably at 20,000 psi/175°C without signal loss.

Conclusion

This RCADS redefines drilling efficiency through:

1. Radical Simplicity: Replacing electronics with pump-controlled hydraulics cuts costs while boosting reliability.

2. Engineered Durability: Monolithic shell and carbide pistons deliver unmatched longevity.

3. Economic Impact: Saves $500K/well by minimizing NPT and tool failures.

4. Industry-Leading Innovation: The 15-piston design sets a new benchmark for wellbore stability.

With proven results in 50+ wells globally, this stabilizer exemplifies how elegant mechanical solutions outperform complex electronics in extreme downhole environments.